- Products

- Catalogs

- News & Trends

- Exhibitions

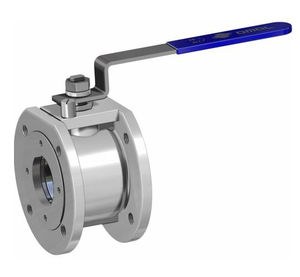

Ball valve Magnumleverfor controlfor water

Add to favorites

Compare this product

Characteristics

- Type

- ball

- Operation

- lever

- Function

- for control

- Media

- for water

- Body

- wafer, stainless steel, carbon steel

- Applications

- for oil industry applications, industrial, for the chemical industry, for the food industry, turbine, for machine tools, for shipbuilding, for automobiles, process, power line, for the pharmaceutical industry, for the gas industry, for the paper industry, for water treatment, for the mining industry, for marine applications

- DN

Max.: 100 mm

(3.937 in)Min.: 15 mm

(0.591 in)- Pressure

Max.: 40 bar

(580.2 psi)Min.: 16 bar

(232.1 psi)- Temperature

Max.: 200 °C

(392 °F)Min.: -40 °C

(-40 °F)

Description

1. Antistatic device (electrical continuity between ball, stem and body)

Static electricity is avoided which can cause sparks and fire in an inflammable/explosive environment

Contact safety throughout the entire life of the valve

2. Double antifriction washer

Less Breakaway Torque is granted

Less wear comparing with the execution with the single washer

3. "V" seals pack; 3 seals + o-ring

It ensures a perfect tightness even after a high number of cycles

4. Spring washer on the shaft seal

Guarantee of the recovery of the gap due to the wear caused by the rotational movement of the shaft avoiding leakage towards the outside part.

Allow to maintain energized the "chevron" seals (V), thus avoiding any leakage to the outside, against huge temperature excursions

5. Stretch Graphite seal

Tightness towards outside is granted, independently by the thermal excursions to which the valve is subjected

Greater precision in the alignment of axes due to a unique positioning in the process machining from raw material to finished valve

Longer lifetime of the valve

Less breakaway torque

Valve body in carbon steel made with NACE certified material as standard

Greater corrosion resistance

Greater ductility of the material

100% in- house manufacturing process technology

Maximum control and accuracy in all the stages of the manufacturing process

Flexibility in supply quickly special executions requested by customers

Catalogs

Related Searches

- Valve

- Hand valve

- Control valve

- Stainless steel valve

- Ball valve

- Water valve

- Pneumatic valve

- Threaded valve

- Valve with flange

- Regulating valve

- Stop valve

- Lever control valve

- ISO valve

- Biogas valve

- Pneumatically-operated valve

- Butterfly valve

- Valve for the chemical industry

- Valve for industrial applications

- Oil valve

- Nickel-plated brass valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.