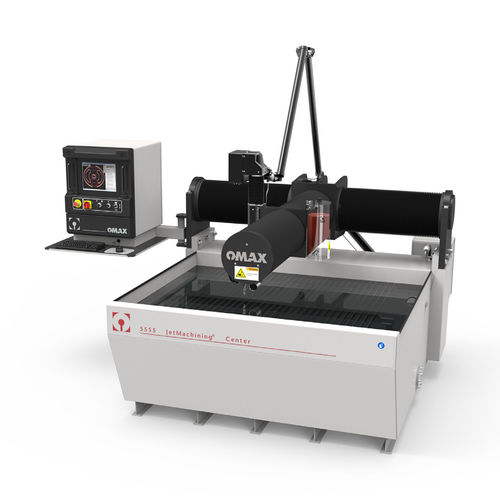

Abrasive water-jet cutting machine 5555for metalfor plasticsfor composite materials

Add to favorites

Compare this product

Characteristics

- Technology

- abrasive water-jet

- Material

- for metal, for plastics, for composite materials, for glass

- Product handled

- sheet

- Control type

- CNC

- Applications

- for industrial applications

- Phase

- three-phase

- Other characteristics

- high-precision, high-speed

- X travel

1,397 mm

(55 in)- Y travel

1,397 mm

(55 in)- Z travel

203 mm

(8 in)- Cutting speed

4,572 mm/min

(3 in/s)- Overall length

2,032 mm

(80 in)- Overall width

1,651 mm

(65 in)- Height

2,997 mm

(118 in)- Weight

2,854 kg

(6,291.99 lb)

Description

The OMAX 5555 is a great fit for shops needing a machine with a smaller footprint but capable of cutting medium-sized stock.

Cutting envelope of 4' 7" x 4' 7" (1397 mm x 1397 mm)

±0.001" (±0.025 mm) linear position accuracy

Standard Features

• Backed by OMAX’s exclusive IntelliMAX Premium Software

• Pre-loaded linear bearings and precision ball screws

• Standard programmable Motorized Z-Axis with a precision OMAX MAXJET 5i Nozzle boosts productivity and process efficiency

• Standard scissor-style hard plumbing adds another level of safety by using contained high-pressure components, as well as contributes to a smaller footprint, lower maintenance, and higher reliability

• Standard Rapid Water Level Control for cleaner, safer, and quieter submerged cutting completes most work below 80 dBA

The fast, efficient, and precise 5555 JetMachining® Center provides top performance in waterjet machining of complex parts from many materials. From simple metals to complex composites, the 4’ 7” square cutting area of the proven 5555 is ideal for rapid prototyping and just-in-time manufacturing of small to medium-sized parts. With simple fixturing and easy access to the cutting table, setup times are significantly reduced, increasing productivity and profitability

OMAX Benefits

• Designed and manufactured at the OMAX factory in Kent, Washington, USA

• Does not create heat-affected zones or mechanical stresses

• Machines a wide range of materials and thicknesses, from metals and composites to glass and plastics

• No tool changes & minimal fixturing dramatically reduce setup

VIDEO

Catalogs

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Cutting machine for industrial applications

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Plastic cutting system

- Precision cutting system

- Aluminum cutting system

- Sheet cutting system

- High-performance cutting system

- Three-phase cutting system

- High-efficiency cutting system

- Compact cutting system

- Steel cutting system

- Bridge cutting system

- Stone cutting system

- Glass cutting system

- Waterjet cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.