- Machine-tools

- Machine Tool Accessory

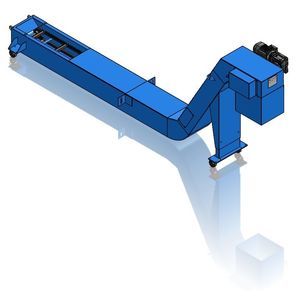

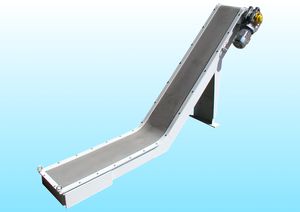

- Belt conveyor

- OMSAT FRANCE

Belt conveyor metal beltchipfor liquids

Add to favorites

Compare this product

Characteristics

- Technology

- belt, metal belt

- Transported product

- chip, for liquids

- Sector

- for assembly lines

- Options and accessories

- with integrated filtration

Description

A single unit composed by one or several conveyors and a self-cleaning drum filter without disposable filtering fabric. Operation- costs saving and coolant life improvement. Ideal for machining centers, for all types of metal chips and coolants. Filtration degree down to 50 microns., flow following request.

OPERATING

Chips and the machining fluid is discharged on the metallic belt conveyor. The chips are removed in a dumpster. The liquid is recovered between the two strands of the belt in the filter.

The remaining particles decant at the bottom and are removed by the drag. Passing through the filter drum, the liquid is purified and gets in the storage tank. A spray bar clean the drum filter against the current, which rotates continuously or intermittently.

Catalogs

No catalogs are available for this product.

See all of OMSAT FRANCE‘s catalogsRelated Searches

- Rail conveyor

- Transport conveyor

- Belt conveyor

- Horizontal conveyor

- Electric drive conveyor

- Drag chain conveyor

- Stainless steel conveyor

- Transfer conveyor

- Automatic conveyor

- Vertical conveyor

- Part conveyor

- Aluminum conveyor

- Assembly line conveyor

- Chip conveyor

- Conveyor for the wood industry

- Waste conveyor

- Wood conveyor

- Magnetic belt rail conveyor

- Drag conveyor

- Wire mesh conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.