- Products

- Catalogs

- News & Trends

- Exhibitions

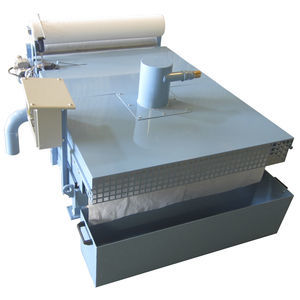

Self-cleaning filter FAU seriesliquiddrumgravity

Add to favorites

Compare this product

Characteristics

- Designed for

- liquid

- Filtration element

- drum

- Filtration method

- gravity

- Applications

- for machine tools

- Material

- paper

- Cleaning

- self-cleaning

- Other characteristics

- automatic

- Filtration size

30 µm

- Flow

Max.: 750 l/min

(198.129 us gal/min)Min.: 50 l/min

(13.209 us gal/min)

Description

This filter has a completely automatic operation and makes it possible to filter all the liquids of cut until a smoothness of 30 microns, without filter media. Economies on the costs of exploitation are possible because there is no paper consumption, nor expenses of recycling of this one. The maintenance costs are reduced only at the periodic expenses of interventions..

OPERATING

The dirty liquid arrives in the vat conveyor side at dredger, the chips fall and are recovered by the dredger. The dirty liquid passes through the grid of the drum, which turns permanently. The liquid filtered inside the drum, flows by gravity in the second vat. The chips stuck on the drum are removed by the jets fixed inside the drum. For correction, a version of this filter is proposed with grid drum with cracks making it possible to work in depression, increasing the flow and decreasing the threshold of filtration. The threshold will be decreased thanks to the formation of a cake, the rotation of the drum being time-lag.

Catalogs

No catalogs are available for this product.

See all of OMSAT FRANCE‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Liquid separator filter

- Solid classifier

- Liquids separator

- Filtration system

- Eddy current separator

- Liquid filtration system

- Hydraulic filter

- Particle classifier

- Automatic separator filter

- Oil separator

- Self-backwashing filter

- Easy cleaning pre-filter

- Particulate separator filter

- Vacuum separator filter

- Separation filter

- Synthetic filter

- Disc filter

- Vacuum filtration system

- Magnetic separator filter

- Belt filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.