- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

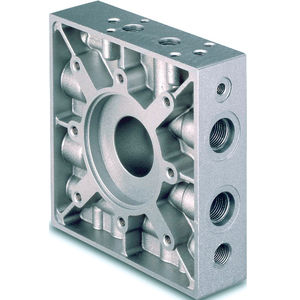

Shaft collar coupling for pumpmotorflange

Add to favorites

Compare this product

Characteristics

- Type

- shaft collar

- Product applications

- for pump, motor

- Installation system

- flange

- Torque

Max.: 725 Nm

(534.7326 ft.lb)Min.: 6.86 Nm

(5.0597 ft.lb)- Rotational speed

1,450 rpm

(9,110.62 rad.min-1)

Description

Bellhousings are the mechanical elements used to

connect an electric motor equipped with standard

flange to a hydraulic pump, thus forming the

pump/motor unit. The bellhousings of this range allow

to establish a perfect assembly between electrical

motors with standard flange up to 270 kW and the

majority of the hydraulic pumps available on the world

market. They are produced in alluminium alloy and

can be divided into two categories:

SINGLE PIECE BELLHOUSING

made of a single piece

COMPOSITE BELLHOUSING

made of several components

– base bellhousing + flange

– base bellhousing + distance ring + flange

Composite bellhousings are employed under the fol-

lowing conditions:

1. The dimension "H1" of the base bellhousing is infe-

rior to the summed length of motor and pump

shafts plus spider.

2. The fixing points of the pump are not compatible

with the fixing holes of the bellhousing.

Necessary indications

for the choice of the correct bellhousing

1. Power of the motor (tab. motors see pag. 21/29).

2. Dimensional data of the hydraulic pump.

Catalogs

COMPONENTS AND ACCESSORIES

142 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.