- Robotics - Automation - Industrial IT

- Industrial Software

- CAD software

- Optical Gaging Products

Analysis software Measure-X® programmingCADediting

Add to favorites

Compare this product

Characteristics

- Function

- analysis, programming, CAD, editing, metrology, data transfer

- Type

- real-time

- Operating system

- Windows

Description

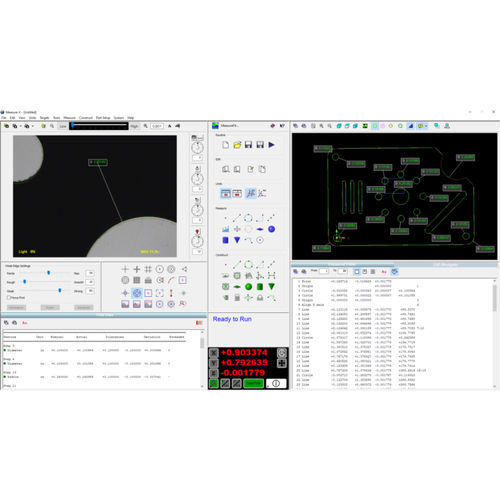

From creating part measurement routines to operating an OGP system in a production work environment, Measure-X® metrology software offers power without intimidation. Measure-X® features a full set of image processing and autofocus tools, geometric functions, ANSI/ISO tolerances, easy editing, and direct, background data transfer to MeasureFit® Plus contour analysis software. Compatible with touch probes, laser, and rotary indexers, Measure-X is the ideal choice for general-purpose video and multisensor metrology.

Easy to Use –The screen layout of Measure-X is simple to learn and use. Measure and see results directly in the real-time video display window. The Program Toolbox is logically designed with large easily identifiable icons for direct access to measurement, construction, and analysis functions.

Walk-Up and Measure – Position, focus, and measure a part feature in the video window. Set axis alignments and define datums. Create constructions to define relationships between discrete part features. Each action becomes a step in a part routine you can save to repeat later automatically Program from CAD – Import DXF and other popular 2D CAD file formats for automatic generation of measurement routines. Simply load the CAD file and select features to be measured. Measure-X does the programming for you!

Measure-X has three functions to allow for a range of different uses from fast walk-up measurements, to complex GD&T analysis:

Measure – With the Measure Tab selected, detailed measurement tasks can be performed.

Program Mode: Measurements can be taken and programs can be created.

Catalogs

Smartscope Flash 250/300

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.