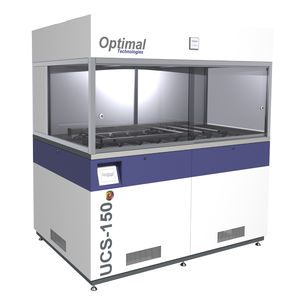

Ultrasonic cleaning machine FPC / IPC / FCPimmersionautomaticmedical

Add to favorites

Compare this product

Characteristics

- Technology

- ultrasonic, immersion

- Operational mode

- automatic

- Applications

- medical, for the chemical industry

- Other characteristics

- with basket

Description

When designing these machines, we put ourselves in your position and include all of the features that will enable you to assure the confidence of any FDA auditor. In doing so, we are able to produce robust and reliable machines that will ensure the safety of all concerned, right down to the all important patient!

These machines are built to the highest quality standards and include all that is required for Factory and Site acceptance. The comprehensive process and standardisation helps us to provide Functional, Design and Software Specification documentation as efficient as possible. We can also help with IQ, OQ and PQ.

Medical devices implant machines include:

FPC - Automatic Fluorescing Penetrant Inspections Machines

IPC - In-process/Inter-Process cleaning machines

FCP - Final Clean and Passivation (nitric or citric acid) Machines

Further options can include:

Automatic chemical dosing

Automatic drain and fill cycle

Variable ultrasonic power

Variable speed basket oscillation

Full process monitoring with data acquisition:

Conductivity

Filtration flow rate

Ultrasonic power

Temperature profiles

Time in stage

Presence of oscillation

Bar code tracking

Routing document security

Clean room load/lock

HEPA air filtration

Catalogs

No catalogs are available for this product.

See all of Optimal Technologies‘s catalogsRelated Searches

- Automatic washing machine

- Process washing machine

- Ultrasonic cleaning system

- Compact washing machine

- Washing machine with rinsing

- Immersion cleaning system

- Medical washing machine

- Multi-tank cleaning machine

- Optical cleaning system

- Coating application system

- Washing machine with basket

- Rotary basket washing machine

- Laminar flow hood

- Cleaning machine for the chemical industry

- Cleaning booth

- Single-tank washing machine

- Washing machine with belt conveyor

- Automatic coating application system

- Stainless steel hood

- Clean air cabin

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.