Laser calibration system LICS-200Afor machines

Add to favorites

Compare this product

Characteristics

- Physical quantity

- laser

- Applications

- for machines

Description

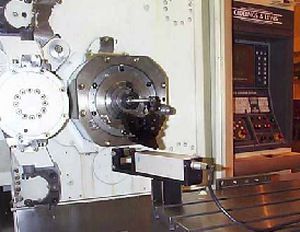

Optodyne's LICS-200A is a complete system for the measurement of straightness accuracy, squareness accuracy and parallelism. It is specially designed for Machine Tool Calibration and Compensation. A laser beam is used to produce a straight line equivalent to the straight-edge and an optical sensor like a dial gauge, is used for determine the vertical and horizontal deviations at the same time . An optical square is used to bend the beam precisely at 90°deg angle for squareness accuracy measurement.

LICS-200A is very easy to use and align, and in combination with LICS-100A Compact Laser Interferometre can provide the measurement on linear displacement, straightness, squareness, pitch and yaw angular errors.

The system is very compact and fits in one very small carrying case.

Catalogs

LICS-200A

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.