Laser calibration system LICS-100AP

Add to favorites

Compare this product

Characteristics

- Physical quantity

- laser

Description

The LICS-100AP is compact and fits into a small brief case. With only 2 elements to be

aligned, it is easy to setup and operation and a machine operator can learn to operate the laser

system in a few hours. It is ideal for calibrate and compensate the machine tool pitch errors. A

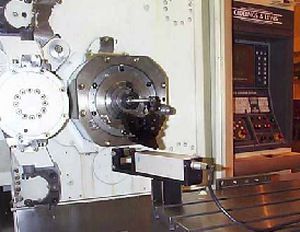

typical setup to calibrate the Z-axis is shown in Fig. 1 below.

Fig. 1, Photo shows the LICS-100AP measuring the Z-axis of a CNC machining center.

The major features are:

• Complete turn-key package fits into a small brief case.

• Single-aperture laser head for easy alignment and setup.

• A machinist can be trained to operate and generate compensation files.

• Using a 90 degrees beam bender to point laser beam in up/down and left/right 4

directions.

• Notebook PC using Windows 8 and preloaded LDDM software.

• Automatic barometric pressure, air and material temperature compensation.

• Automatic data collection and generate pitch error compensation files for most

controllers.

• Data analysis based on ISO 230 and ASME B5 standards.

• Laser stability is 0.1 ppm

Catalogs

No catalogs are available for this product.

See all of OPTODYNE‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.