Volume measuring system MCV-500Claserautomaticnon-contact

Add to favorites

Compare this product

Characteristics

- Measured physical value

- volume

- Technology

- laser

- Operating mode

- automatic

- Other characteristics

- non-contact

Description

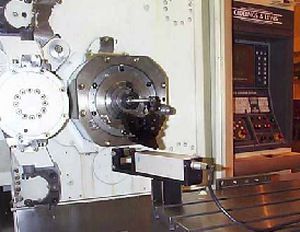

A Laser System for Volumetric Positioning and Dynamic Contouring Measurement

MCV-500, LB-500, SD-500 and SQ-500 A world class laser system for the volumetric calibration and compensation, squareness and straightness error measurement, and for non-contact circular contouring measurement

Improving Your Machine Tool Performance

What is the performance of your machine tools?

It is better to catch errors before they appear in parts by measuring both the volumetric positioning & accuracy and the dynamic contouring accuracy.

Volumetric positioning accuracy

Using the laser vector technique (patent pending),3 displacement errors, 6 straightness errors and 3 squareness errors can be determined in a few hours while conventional laser interferometers may take a few days.

Dynamic contouring accuracy

Using the laser/ballbar (patent accuracy of various radii at high feed rates can be determined. Furthermore, the true radius, actual feed rate and acceleration can all be determined.

Break through in laser technology

Unique single-aperture laser head using flat-mirror target simplifies the setup and operation. The software allows for automatic data collection and analysis. Laser/ballbar measurement is non-contact, no need for centering, and no cable's in the way.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.