Laser calibration system MCV-4000for machinescompactprecision

Add to favorites

Compare this product

Characteristics

- Physical quantity

- laser

- Applications

- for machines

- Options

- compact, precision

Description

Linear, Angular, Straightness, Flatness & Squareness Calibration

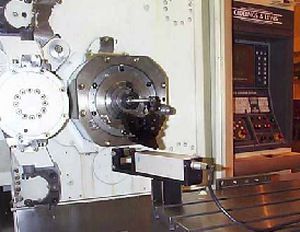

OPTODYNE's MCV-4000 Linear, Angular, Straightness, Flatness, and Squareness Calibration System calibrates CNC machine tools, CMMs (Coordinate Measuring Machines) and other precision measurement machines and stages. The unique dual-beam design provides a rapid means to measure the surface flatness of surface plates and the linear and angular errors of machine axes. The MCV-4000's Quad-detector and optical square also allow for the precision measurement of squareness and straightness.

OPTODYNE's machine calibration systems are based on our proprietary and patented Laser Doppler Displacement Meter (LDDMTM) technology. The total system is compact, providing easy, convenient storage and transportation. Easy setup procedures reduce overall machine calibration time. Calibrated and traceable to N.I.S.T., the OPTODYNE laser calibration system maintains high accuracy as well as lower costs.

The MCV-4000's dual beam laser design provides the user a sim- ple, easy-to-operate linear and angular capability in a single instrument. It's like "having two interferometers in one". One beam monitors linear positioning while the other beam monitors angular data. The Windows" software, running on any IBM com- patible computer, is user friendly and designed to collect and ana- lyze data in accordance with a variety of industry standards.

Catalogs

No catalogs are available for this product.

See all of OPTODYNE‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.