ASP 200 CNC-B

Highlights

4-Axis CNC polishing operations (X, Z, B, C)

OptoTech AspheroSpeed® Polishing Technology

Tool spindle can be mounted with flexible surface polishing tool or topographic correction polishing tool

Optimal machine kinematics for processing aspheres with highly reproducible results

B-Axis swiveling ±55°

Rigid, low torsion machine construction on low vibration cast iron base

State-of-the-art drive and spindle bearing technologies. Spindles with multiple bearings

Options: Software Package POLyCAM-3D; Interface to Modern Profile Measuring Systems (e.g. Taylor Hobson Talysurf PGI Series, Mahr MarSurf); Remote Diagnosis

Performance Data

Working Range ∅ 10 to 220 mm (Asphere-Mode); Ø 10 to 120 mm (SynchroSpeed-Mode)

Working Range Radius 10 mm to ∞ (Best Fit Radius)

Tool Spindle Speed 2.000 min-1

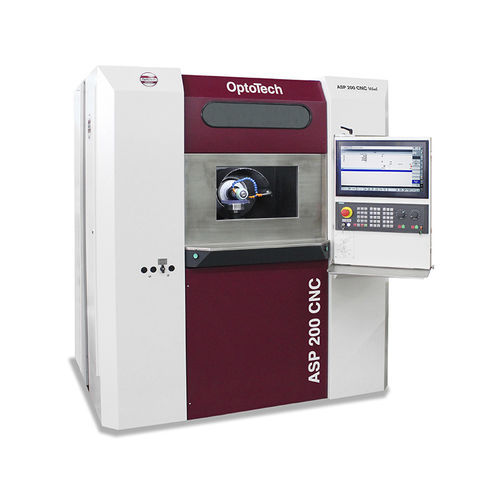

ASP 200 CNC Wheel

Highlights

4-Axis CNC polishing operations (X, Y, Z, C)

Both, cylinders and freeform surfaces can be processed using the raster method

Rigid, low torsion machine construction on a low vibration cast iron basis

State-of-the-art drive and spindle bearing technology. Spindles with multiple bearings

Working room Teflon coated for easiest cleaning

Options: Interface to Modern Profile Measuring Systems (e.g. Taylor Hobson Talysurf PGI Series, Mahr MarSurf); Remote Diagnosis

Performance Data

Working Range Ø 10-250 (300) mm

Working Range Radius cx 10 mm to ∞ (Best Fit Radius); cc -45 mm to ∞ (Best Fit Radius)

Tool Spindle Speed 2.000 min-1