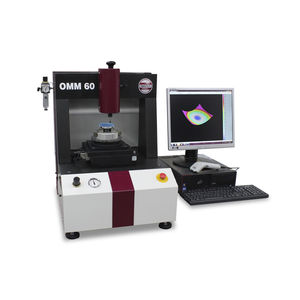

Optical grinding machine ASM 100 CNCsurfaceCNC4-axis

Add to favorites

Compare this product

Characteristics

- Type

- surface

- Applications

- optical

- Control type

- CNC

- Number of axes

- 4-axis

- Other characteristics

- high-precision, fine

- Spindle speed

Min.: 0 rpm

(0 rad.min-1)Max.: 20,000 rpm

(125,664 rad.min-1)- X travel

360 mm

(14.17 in)- Y travel

100 mm

(3.94 in)

Description

Highlights

The ASM 100 CNC-TC is the ideal pre- and fine grinding generator for glassmolds (cast device for ophthalmic lenses)

The high accuracy and flexibility make this machine the no. 1 in the industry. Well known companies use this machine

4-Axis CNC generating operations (X, Y, Z, C)

Rigid, low torsion machine construction made of grey cast iron

Processing is done with wheel tools using the circumferential grinding method. This greatly improves the machine kinematics and gives highly reproducible results

Aspheres can be generated using a spiral tool path with only 2 CNC axes. Therefore the grinding results are much more accurate than those achievable with other methods

Interface to modern profile measuring systems (e.g. Taylor Hobson Talysurf PGI Series)

Options: Hydro Expansion Chucking Technology; Remote Diagnosis

Performance Data

Working Range Ø 10 to 150 mm (Using 2 Grinding Spindles with 4 Tools) respectively Ø 10 to 250 mm (Using 1 Grinding Spindle with 2 Tools)

Working Range Radius cx 10 mm to ∞ (Best Fit Radius); cc -45 mm to ∞ (Best Fit Radius)

Tool Spindle Speed ≤ 20.000 min-1

Catalogs

No catalogs are available for this product.

See all of OptoTech‘s catalogsRelated Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Flat grinding machine

- Polishing unit

- High-precision grinding machine

- Automatic polishing unit

- Surface polishing machine

- 3-axis grinding machine

- CNC polishing machine

- Grinding polishing unit

- Plastic polishing unit

- Optical polishing machine

- Glass polishing machine

- 5-axis grinding machine

- Lens polishing machine

- 4-axis grinding machine

- Surfacing polishing machine

- Optical grinding machine

- Precision optic polishing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.