Conveyor furnace OCF Premium Plus 3curingcontinuousfor clean rooms

Add to favorites

Compare this product

Characteristics

- Configuration

- conveyor

- Function

- curing

- Other characteristics

- continuous, for clean rooms

Description

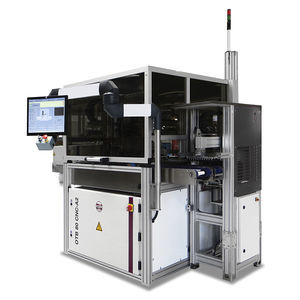

The OCF Premium Plus 3 is especially designed for curing coatings on ophthalmic lenses in a continuous cleanroom conveyor furnace after the hardcoating process.

The modular system has 3 individually controlled heating zones whose working temperature can be set independently of each other offering maximum process flexibility.

Continuous furnace designed for curing of coatings on ophthalmic lenses.

For lens trays that can be stacked on up to 3 layers. There is space for a maximum of 12 trays in a row in the furnace. A maximum of 36 trays can thus be processed at once in the continuous furnace.

Suitable for ophthalmic lenses hardcoated with non-solvable lacquers.

The continuous furnace meets the requirements according to class ISO 6 (according to DIN EN ISO 14644-1) with built-in HEPA circulating air filters.

The conveying speed can be set variably (10mm/min to 50 mm/min), as can the working temperature (up to 130° C).

The modular continuous furnace consists 3 modules, divided into 3 regulated heating zones (inlet, outlet and middle module. Each with heating and control zone).

Modular design of the system which allows different furnace setups (number of modules / conveyor length).

Equipped with a state-of-the-art PLC controller with 7” touch panel. Siemens Simatic S7-1513 with colored touch panel available on option.

Construction and equipment of the cleanroom furnace are either CE or UL compliant.

Catalogs

No catalogs are available for this product.

See all of OptoTech‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.