Mechanical coupler LYNX series

Add to favorites

Compare this product

Characteristics

- Type

- mechanical

Description

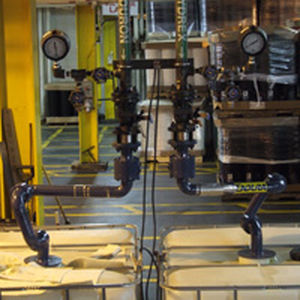

LYNX Series Coupler – The Best in Bottom Loading

LYNX is optimized to bring your liquid terminals and tank trucks the very best in dry-break API technology. From its ultra-durable stainless-steel collar to its ability to protect your loading-arm connection even when facing surge pressures up to 500 psi, you can count on LYNX for years of service and to help minimize fluid loss.

Fast Disassembly, Less Downtime

If you have 30 seconds and a screwdriver, you can disassemble LYNX. Thanks to a U-pin design, loading-arm operators can perform coupler maintenance without special tools and do it quickly.

5-Year Warranty

Fast in-field replacement of the main seals, on or off the arm

Quick and easy disassembly of entire coupler through U-pin design

Automatic latching

U-pin is secured when the TTMA flange is fastened to prevent the pin from coming out during service

A variety of seals available to suit a range of applications

Two operating handle sizes to suit customer preference

Four “true-interlocking” stainless-steel latches ensure secure coupling and maximum safety

High-quality components including a stainless-steel collar and hard anodized aluminum body for increased service durability and life

Nominal product leakage during disconnect increases site safety

Low risk of leakage because of a proven seal design

Ergonomic operating handle and carry loop results in less physical strain on users

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.