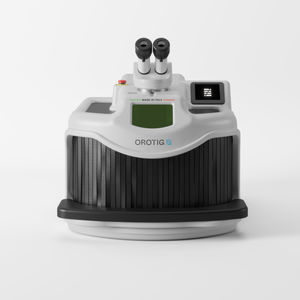

Laser welding Antaresbrasstitaniumnickel

Add to favorites

Compare this product

Characteristics

- Technique

- laser

- Material

- stainless steel, steel, cast-iron, aluminum, copper, titanium, brass, nickel, bronze

- Applications

- industrial

Description

Antares is an industrial laser specifically conceived to repair moulds and big sized pieces. The welding head is moved in XYZ axes by means of a motorized arm manged by a joystick. Besides the motorized movements, the arm can be positioned at a range of different angles thanks to articulated joints, allowing to direct the welding spot in difficult-to-reach areas.

• TFT 7” color touch-screen display

• Leica 10x microscope

• Exhauster and Argon fittings

• On-wheels base to move it easily and freely. Wheels lock system to guarantee a stable position during the welding process

• Standard software with semi-automatic functions (welding path on tilted surfaces, circled, straight and polylined paths)

• Spherical magnetic holder

• Integrated camera and external viewing monitor

• Steel-made motorized bench

• 230V Transformer

• Software plugin to import vector paths

• Rotary motor with chuck (Ø 80 mm and Ø 125 mm)

• LASER SOURCE Nd:YAG @ 1064 nm

• MAX PULSE POWER 100 J

• PEAK POWER 12,5 kW

• AVERAGE POWER 300 W

• POWER SUPPLY 400 VAC±10% 3+N ph, 50/60Hz, Absorbed Power 9 kW

• PULSE DURATION 0,5 - 25 ms

• FREQUENCY MIN. / MAX. 0 - 40 Hz

• COOLING SYSTEM External chiller

• FIBER DIMENSIONS 800/1000 µm - 5 mt lenght

• WELDING SPOT DIAMETER 0,7 - 2 mm

• DIMENSIONS (LxPxH) 1020 x 1650 x 1650

VIDEO

Catalogs

ANTARES (LWI 4.0)

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.