- Machine-tools

- Machine Tool Accessory

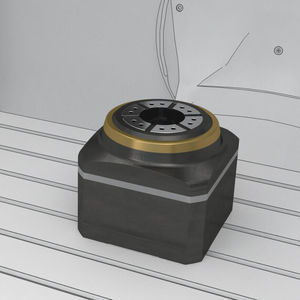

- Manual tightening turning chuck

- Ortlieb Präzisions-

6-jaw turning chuck QUADRO®dead length colletsteelhydraulic

Add to favorites

Compare this product

Characteristics

- Number of jaws

- 6-jaw

- Other characteristics

- dead length collet, hydraulic, steel

- Rotational speed

Max.: 6,000 rpm

(37,699.11 rad.min-1)Min.: 0 rpm

(0 rad.min-1)- Outer diameter

Max.: 220 mm

(9 in)Min.: 112 mm

(4 in)

Description

QUADRO® Dead Length Collet Chucks for CNC-Lathes

The main range of application of the QUADRO® dead length collet chucks are NC/CNC-machines, lathes, special machines etc. The clamping pressure is hydraulically transferred by a pressure tube on the pressure sleeve. The high qualitystandard and the universal range of application are the reasons that QUADRO® dead length collets

are counting to the first class products in the clamping technology.

Your benefit:

• No axial movement of workpieces due to clamping by pressure

• It is possible to use Rubber-Flex® RFC collets

as well as steel collets according to DIN 6343

• Short changeover time for collet change due to bayonet cap

• It is possible to change to vibration-free twin-clamping system with

Rubber-Flex® RFC collets

On request we are modifying the dead length collet chucks according to your

special clamping application.Of course we are pleased to produce the adapter

for your machine. Just fax us the spindle dimensions or fill out the form.

You can manufacture the appropriate adapter also by yourself.

Reduction Parts for Standard Chucks

The reduction parts allow the use of smaller Rubber-Flex® RFC or steel collets DIN 6343 in the same main body of the chuck.

For that modification you need pressure sleeve and bayonet locknut.

Accessories: Twin-Chucking Facility

Two Rubber-Flex® RFC 36 or RFC 52 positioned behind each other guarantee maximum vibration-free chucking of bar material.

Chucking length is 90 respective 110 mm! This type is recommended for larger bar diameters.

Catalogs

Related Searches

- Chuck

- Milling chuck

- ISO chuck

- Drilling chuck

- HSK chuck

- DIN chuck

- Collet tool holder

- Milling tool holder

- ISO tool holder

- HSK tool holder

- Drilling tool holder

- 3-jaw turning chuck

- DIN tool holder

- High-speed chuck

- High-speed tool holder

- Modular chuck

- Tool holder for turning applications

- Manual turning chuck

- Finishing tool holder

- ER tool holder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.