- Products

- Catalogs

- News & Trends

- Exhibitions

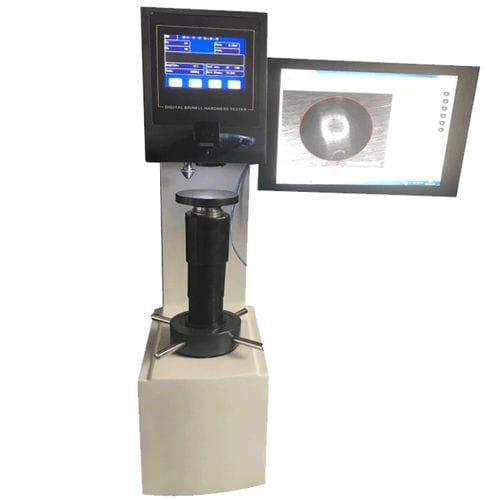

Brinell hardness tester measurementautomaticmechanical

Add to favorites

Compare this product

Characteristics

- Type

- Brinell

- Product applications

- measurement

- Other characteristics

- LCD digital display, automatic, mechanical

- Load

1.839 kN, 2.452 kN, 7.355 kN, 9.807 kN, 29.42 kN

- Weight

210 kg

(463 lb)

Description

Brinell Hardness Tester is a precision mechanical structure and microcomputer control closed-loop system of optical, mechanical, and electrical integration products. It is also the world’s most advanced Brinell hardness tester. The instrument cancellations the weight, adopts the electric loading and unloading test force, and is fed back by the pressure sensor with 0.5‰ accuracy. The CPU control can automatically compensate for the test force lost in the test. Indentation can be measured directly on the instrument through the micrometer eyepiece. The indentation diameter can be displayed on the LCD display, and the Brinell hardness test (HBW) range can be automatically displayed in the current setting state. You can also set the storage time on the page.

Features

• Automatic over-position protection

• experimental process automation

• no human operation error

• large LCD display

• menu intelligent prompt

• easy to operate

• high-precision reading microscope measurement system

Brinell Hardness Tester Specification

1. Measuring range: 8-450HBS,8-650HBW

3. Max height of test samples: 230mm

4. Distance between press head to bottom plate: 120mm

5. Power: 220V/380V/customized

6. Machine size: 700*268*842mm

Related Searches

- Test machine

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Temperature test cabinet

- Automatic test machine

- Climatic test chamber

- Portable testing system

- Compression test machine

- Humidity test cabinet

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Industrial testing system

- Voltage testing system

- Environmental test cabinet

- Rockwell indentation hardness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.