Many customers set great store by the flexibility to handle different alloys and slabs of widely varying dimensions. It is these criteria which prompt them to opt for a pit-type furnace.

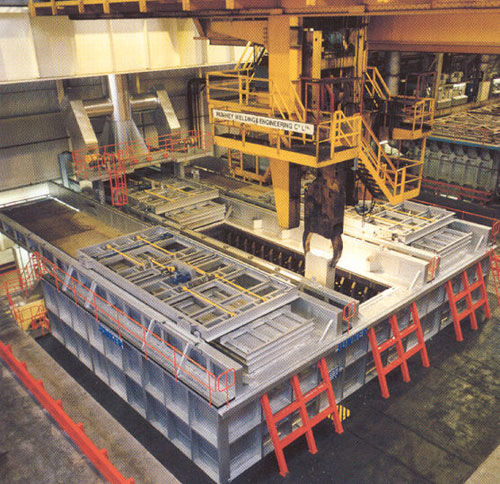

As a rule, each pit furnace chamber can accommodate about 10 - 20 rolling slabs and is charged with a separate crane. An installation will typically comprise multiple furnace chambers equipped with a common visualization system.

Pit furnaces are designed to provide direct reheating or homogenizing of their slab charge. For this purpose they are equipped with a suitable cooling system capable of producing a defined cooling ramp.

Optimum uniformity of the metal temperature is achieved by optimized flow management techniques reflecting many years of experience, simulation and measurement know-how.

Each furnace chamber is divided up into individual furnace zones and can be separately controlled.