Pit furnace meltingholdinginduction

Add to favorites

Compare this product

Characteristics

- Configuration

- pit

- Function

- melting, holding

- Heat source

- induction

- Other characteristics

- for metallurgy, for copper

Description

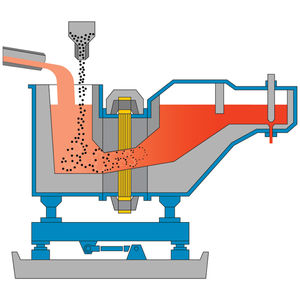

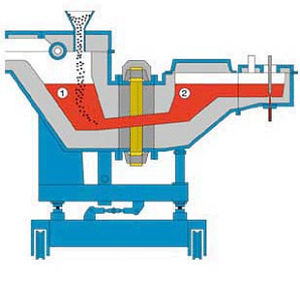

Channel-type furnaces are used both for melting scraps and bulky charge material as well as for storing/holding various alloys and finally as heatable casting furnaces. The benefits of this furnace type are the high electro-thermal efficiency and good metal bath mixing which produces homogeneous alloys with a constant, uniform temperature.

Take a look at the following examples for information on the versatile, process-specific design and use of this furnace type:

Scrap melting in the chanel-type induction furnace

Storing of copper

Storage and casting furnace for continuous casting

Storing of gray cast iron

Storing of Al-Si alloys

Piece galvanising in the channel-type induction furnace

Strip galvanising in the channel-type induction furnace

Horizontal continuous casting

Resonant circuit converters

Vertical continous casting

Vertical continuous casting of precision tubes

Horizontal low-pressure casting

Casting of sanitary fittings

Catalogs

No catalogs are available for this product.

See all of OTTO JUNKER GMBH‘s catalogsOther OTTO JUNKER GMBH products

Furnaces/Plants for copper and copper-based alloys

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Controlled atmosphere furnace

- Automatic furnace

- Vacuum furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Melting furnace

- Horizontal furnace

- Tempering furnace

- Inert gas furnace

- Metallurgy furnace

- Induction furnace

- Bell furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.