Chamber furnace pouringinductioncontinuous

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- pouring

- Heat source

- induction

- Other characteristics

- continuous, for copper

Description

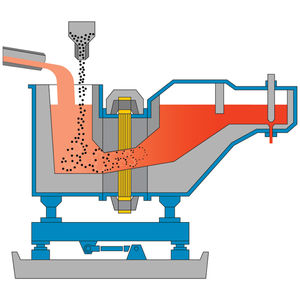

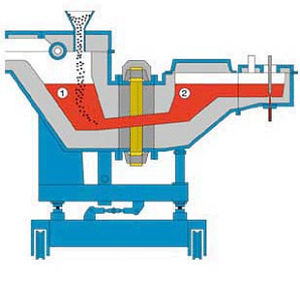

Medium-frequency coreless induction furnaces for copper and brass are designed to meet the needs of the semi-finished products industry. The continuous feeding of continuous casting lines requires precisely dosed pouring of the liquid metal over an extended period, achieved ideally with high-resolution tilting systems.

Anlagen_cu_giesserei_mft1.jpg

The arrangement of the pouring and filling systems in the tilting bearing and a gas-tight furnace design for optimum atmosphere control support the production of particularly high-grade copper alloys.

Catalogs

No catalogs are available for this product.

See all of OTTO JUNKER GMBH‘s catalogsOther OTTO JUNKER GMBH products

Furnaces/Plants for copper and copper-based alloys

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Controlled atmosphere furnace

- Automatic furnace

- Vacuum furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Melting furnace

- Horizontal furnace

- Tempering furnace

- Inert gas furnace

- Metallurgy furnace

- Induction furnace

- Bell furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.