Chamber furnace meltinginductionhorizontal

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- melting

- Heat source

- induction

- Other characteristics

- horizontal, continuous

Description

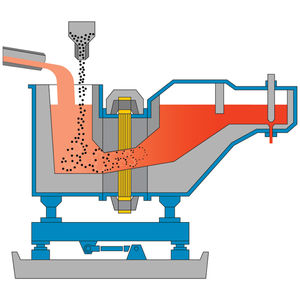

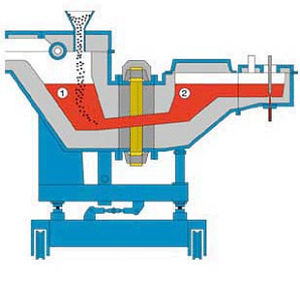

The demands made on the quality of the melt during the manufacture of semi-finished products in the continuous casting process are growing constantly. In order to guarantee the maximum utilisation of continuous casting lines, a sufficient volume of metal at a homogeneous casting temperature must be available ready for casting at all times.

For these applications, INDUGA has optimised the induction heated storage furnace with forehearth. It serves as a buffer between melting and casting. This type of furnace is used in vertical continuous casting for direct metering of the metal into the moulds and in horizontal continuous casting for charging multi-chamber casting furnaces. The furnace home position is tilted compared to its casting position.

Catalogs

No catalogs are available for this product.

See all of OTTO JUNKER GMBH‘s catalogsOther OTTO JUNKER GMBH products

Furnaces/Plants for copper and copper-based alloys

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Controlled atmosphere furnace

- Automatic furnace

- Vacuum furnace

- Annealing furnace

- Continuous furnace

- Forced convection furnace

- Melting furnace

- Horizontal furnace

- Tempering furnace

- Inert gas furnace

- Metallurgy furnace

- Induction furnace

- Bell furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.