Chamber furnace holdingcombustioncontinuous

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- holding

- Heat source

- combustion

- Other characteristics

- continuous

Description

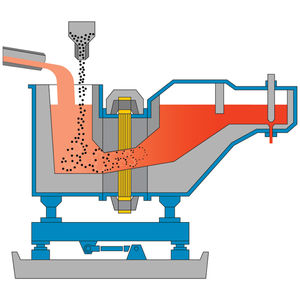

The production of vertically cast copper-based alloys demands not only a highly sophisticated continuous casting technology but also a casting and holding furnace is required which is able to supply a homogeneous melt under constant, defined conditions with exact temperature control over the whole casting time and with a technology tailored to the demands of continuous casting. The casting furnace consists of two chambers and a forehearth which are heated by an inductor integrated into the furnace vessel. The mobile casting furnace can be tilted hydraulically for production, mould changing and furnace discharge.

Catalogs

No catalogs are available for this product.

See all of OTTO JUNKER GMBH‘s catalogsOther OTTO JUNKER GMBH products

Furnaces/Plants for copper and copper-based alloys

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Controlled atmosphere furnace

- Automatic furnace

- Vacuum furnace

- Continuous furnace

- Annealing furnace

- Forced convection furnace

- Melting furnace

- Horizontal furnace

- Tempering furnace

- Inert gas furnace

- Metallurgy furnace

- Induction furnace

- Bell furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.