Low-pressure die casting machine LPDC 1011

Add to favorites

Compare this product

Characteristics

- Pressure range

- low-pressure

Description

Fully automatic machine with linear portal, one manipulator and one furnace

Cycle time approx. 50 sec.

Capacity per shift (8 hours) approx. 450 castings

This machine stands out for its high capacity and its easy operation and maintenance.

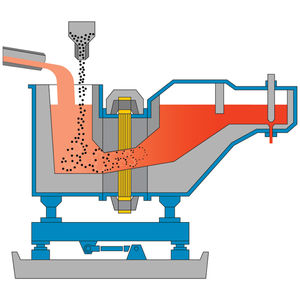

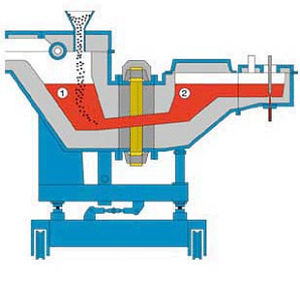

The working principle of the machine:

Manual setting of the cores

Automatic casting with computer controlled pressure-time curve

Automatic unloading of the casting

Cooling and coating in a blackwash bath

The furnace can be selected for a melting capacitiy of 300 or 500 kg per hour. Manual or automatic furnace charging with solid material. Charging of liquid material is possible.

Catalogs

No catalogs are available for this product.

See all of OTTO JUNKER GMBH‘s catalogsOther OTTO JUNKER GMBH products

Furnaces/Plants for copper and copper-based alloys

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.