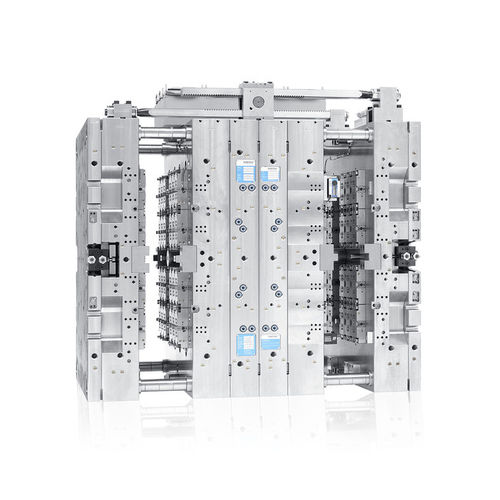

männer high-precision molds are extremely durable, high-performance molds specifically designed for large-volume production of precision injection-molded parts.

We develop our high-precision molds with an eye on part-to-part consistency and reproducibility, which are essential to automated downstream processing of the injection-molded parts.

Repetition accuracy

Long life

Optimized temperature control for short cycle times

Easy maintenance with männer's "easy-change" system

Thin-wall technology

Regardless of whether your plastic product is produced in a singleface mold, stack mold or multicomponent mold, all of our molds are robust, extremely durable, and easy to maintain, making them ideal for mass production.

The repetition accuracy of our high-precision molds enables fully automatic downstream processing of your product.

Singleface Molds

Optimized mold design for superior precision, stability, and cooling

Long life

Maximum repetition accuracy

Easy maintenance

Up to 128 cavities

Stack Molds

For high-volume production

Stack molds with two or four parting lines

Two or four times the output quantity per cycle when compared to

singleface molds using the same closing force

Energy savings of up to 50%

Reduced space requirements

Specially developed hot runner stack technology

Multicomponent Molds

Economical production of parts comprised of two or more different types of plastic materials and/or colors

High cavitation with use of a wide range of technologies such as turntable, core-pulling, and transfer methods

Insert over molding

For production of up to five components