- Industrial machines and equipment

- Welding and Assembly

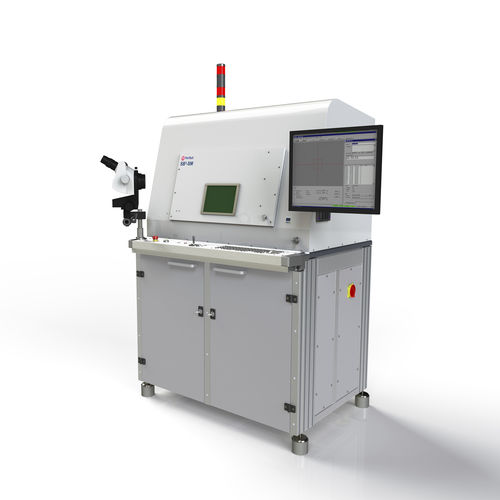

- Laser soldering machine

- Pac Tech – Packaging Technologies GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Laser soldering machine SB² – SMreflowfully-automaticfor printed circuits

Add to favorites

Compare this product

Characteristics

- Technique

- reflow, laser

- Operating mode

- fully-automatic

- Applications

- for printed circuits, for electronic components

- Other characteristics

- compact

Description

Being a lower cost version of the SB²-Jet without compromising its placement accuracy, the SB²-SM is a sequential solder ball attach and laser reflow system that can operate either in a fully automatic or in a semiautomatic mode. With larger work area than the SB²-M, yet relatively compact foot print than the SB²-Jet, it is ideal for research & development, prototyping and small volume manufacturing.

• Jet mode/Standard mode

• Available solder ball diameter: 60 – 760μm

• Suitable for chip/wafer/substrate soldering

• Optional ball rework (de-balling & re-balling) capability

Options

• Solder Ball Rework Station

• Pattern Recognition and Fiducial Alignment

• Upgrade to 8” working area

• Heated chuck/work stage

• Specific heated work holder for BGA-like devices

• Automatic Z-height measurement

Benefits

• High flexibility

• Small solder ball handleability

• Rework function

VIDEO

Other Pac Tech – Packaging Technologies GmbH products

LASER SOLDERING MACHINE – SB²

Related Searches

- Mounting machine

- Soldering machine

- Automatic mounting machine

- Reflow soldering machine

- Automated soldering machine

- Printed circuit soldering machine

- Electronic component soldering oven

- In-line soldering oven

- Compact soldering machine

- Laser soldering machine

- Electronic components assembly machine

- Flexible soldering machine

- Small-scale production soldering oven

- Test assembly machine

- High-speed soldering machine

- Laser welding assembly machine

- Fully-automatic soldering machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.