- Packing - Handling - Logistics

- Packing and Packaging

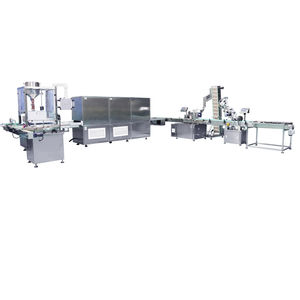

- Automatic filling and capping machine

- Paixie Packing Machinery

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic filling and capping machine XP seriesbottlehigh-speed

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product applications

- bottle

Description

304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

5. Efficient spray nozzle rinse thoroughly and save water for flushing

Introduction:

Automatic Filling and Capping machine for the application of light liquid filling and capping for plastic or glass bottles.Liquid filling machine line can be applied to fruit juice,beverage,syrup,oral liquid,food,cosmetic and other liquid filling. Liquid filling production line is made of bottle machine,filling machine,capping machine,aluminum foil sealing machine,sticker labeling machines composed of single bottling line

Features:

1. Using the wind sent access, with clamp hanging the bottle neck; which can keep the bottle shape and high-speed.

2. Bottles transmission adopts clip bottleneck technology, clean and fast.

3. Filling uses liquid cylinder feeding structure, filling valve uses new normal pressure filling, ensure the filling correct and stable,

4. Spiraling decline when output bottle, transform bottle no need to adjust the height of conveyor chains. Cap automatically.

5. Host adopts advanced PLC automatic control technology, the key electrical components from famous company such as Japan\'s Mitsubishi, France Schneider, OMRON.

Washing station

1. Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2. Optimum uptime: 30 % reduction in changeover and maintenance downtime

3. Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

Catalogs

No catalogs are available for this product.

See all of Paixie Packing Machinery‘s catalogsOther Paixie Packing Machinery products

Small bottle filling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.