- Packing - Handling - Logistics

- Packing and Packaging

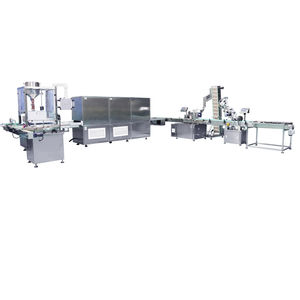

- Automatic filling machine

- Paixie Packing Machinery

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic filling machine PX-BFC80for plastic bottlesfor glass bottlescontainer

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- for glass bottles, for plastic bottles, container

- Product applications

- for liquids

- Type

- in-line

- Other characteristics

- PLC-controlled

- Throughput

Max.: 6,000 p/h

Min.: 1,500 p/h

- Volume

Max.: 5,000 ml

(169.1 US fl oz)Min.: 10 ml

(0.3 US fl oz)

Description

The latest PX-BFC80 SmartFiller integrated filling line is rated for 40 fills per minute, depending on fill volume. Use in-line filling for 30-650 ml containers. The machine is servo driven, which helps maintain accuracy and speed, you just need to enter the ideal filling volume and speed in the HMI interface, that's what the servo motor is for. At the top of the machine we use a mixing hopper, which makes this device suitable for liquids and pastes. The stirring motor drives the stirring paddle, so that the filling material has strong fluidity. It can fill different bottles, we set a scale in the adjustment part to record the positional relationship of different specifications of bottles to the equipment. This greatly improves the convenience of the device. The viscosity of the glue is very high, we must use a heated hopper to enhance the flow of the glue

The biggest advantage of the ceramic pump is its high adaptability with PVC glue, the glue will not stick to the ceramic, which avoids the adhesion of the cylinder after the equipment is shut down, resulting in paralysis, and the process of cleaning and disassembling the cylinder often causes headaches for customers

Catalogs

Other Paixie Packing Machinery products

Small bottle filling machine

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Filling system for the chemical industry

- Multi-head filler

- Side labelling machine

- Filler for the pharmaceutical industry

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Filler for the cosmetics industry

- PLC-controlled filler

- Container filler

- Piston filler

- Automatic capper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.