- Packing - Handling - Logistics

- Packing and Packaging

- Automatic filling machine

- Paixie Packing Machinery

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

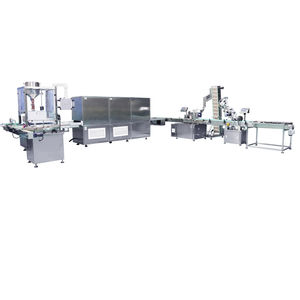

Fully-automatic filling machine PX-BFC85 seriesbottleoilfor perfumes

Add to favorites

Compare this product

Characteristics

- Operational mode

- fully-automatic

- Container type

- bottle

- Product applications

- oil, for perfumes

- Type

- piston

- Throughput

Max.: 70 p/min

Min.: 15 p/min

- Volume

Max.: 120 ml

(4.1 US fl oz)Min.: 2 ml

(0.1 US fl oz)- Machine length

2,400 mm, 2,800 mm, 3,200 mm

(94 in, 110 in, 126 in)- Machine width

1,500 mm, 2,000 mm

(59 in, 79 in)- Machine height

1,800 mm, 1,900 mm

(71 in, 75 in)- Machine weight

600 kg, 700 kg, 750 kg

(1,322.77 lb, 1,543.24 lb, 1,653.47 lb)

Description

The fully automatic small vail bottle liquid filling capping machine is with CE certification.The machine is applied to glass or plastic bottles with different sizes and shapes, and suitable for different filling volume. By adjusting the filling volume on touch screen, it can fill liquid with quick speed and high precision. It is widely used for essential oil, eye dropper, perfume, nail polish, lotions and other vial bottle filling.

This machine is mainly used for filling production line of test tubeand other small-dose products, which can realize automatic feeding,peristaltic pump filling, positioning cap, high-speed cap turning andautomatic labeling. The machine adopts mechanical transmission to ensure accurate andstable operation, low noise, low loss, and no air pollution.The whole machine is made of 304 stainless steel, in line with GMP requirements.

Workflow:

bottle feeding→filling→adding dropper cap→screw capping→self adhesive labeling→ribbon printing (optional)→inkjet printing (optional)→bottle collecting

Features:

1. Can customize products according to customer bottle samples.

2. Peristaltic pump measuring, accurate measurement, easy to control.

3. Filling system has suction / anti-drip device.

4. Easy to adjust filling parameter with PLC and touch screen automation control system.

5.The whole body is made of 304 stainless steel, compact structure, beautiful appearance, with stable and reliable performance,easy maintenance.

6. Adopted piston quantitative, use well-known brand accessories, filling accuracy, adaptability.

7.The whole line is compact, high speed, high degree of automation, save the manpower cost.

8. It complies with CE certification.

Catalogs

No catalogs are available for this product.

See all of Paixie Packing Machinery‘s catalogsOther Paixie Packing Machinery products

Small bottle filling machine

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Filling system for the chemical industry

- Side labelling machine

- Filler for the pharmaceutical industry

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Filler for the cosmetics industry

- PLC-controlled filler

- Container filler

- Piston filler

- Automatic capper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.