- Packing - Handling - Logistics

- Packing and Packaging

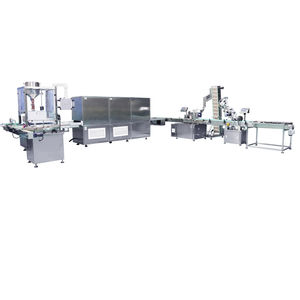

- Automatic filling machine

- Paixie Packing Machinery

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic filling machine bottlefor liquidsfor perfumes

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- bottle

- Product applications

- for liquids, for perfumes, for aerosol sprays

- Other characteristics

- PLC-controlled

Description

This machine adopts position pump, which is suitable for different kinds liquids, with high filling speed and high filling precision. The pump uses quick-fit removal structure: easy cleaning and disinfection. The filling nozzles adopt anti-drip and anti-drawing filling device. The machine adopts PLC and human-computer touch screen control system.

This valve putting part worked with stable speed and high efficiency. The machine adopts PLC and human-computer touch screen control system. The valve sorter and feeding parts can be easy to change for the different size.

consist of cans arranging machine, rotary liquid filling machine, valve inserting machine, rotary crimping and gas filling , automatic weight checker, water bath, nozzle presser, cap presser, ink jet printer, packing table, etc. Propellants could be LPG, DME, CO2, N2, compressed air, etc, widely applied in spray paint, air freshener, insecticide, body spray, snow spray, etc

Catalogs

No catalogs are available for this product.

See all of Paixie Packing Machinery‘s catalogsOther Paixie Packing Machinery products

Small bottle filling machine

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Filling system for the chemical industry

- Side labelling machine

- Filler for the pharmaceutical industry

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Filler for the cosmetics industry

- PLC-controlled filler

- Container filler

- Piston filler

- Automatic capper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.