a tincture filling machine. It is sometimes called a monoblock liquid filler. A monoblock machine combines multiple packaging functions on the same machine. It is the centerpiece of a liquid filling line sometimes referred to as a “Tincture Line” because it fills vials and then inserts “eye-dropper” caps. The eye-dropper type caps are important because the consumer uses “tinctures” by placing a few drops under their tongue. This route of administration avoids contact with the liver and ensures better absorption into the blood.

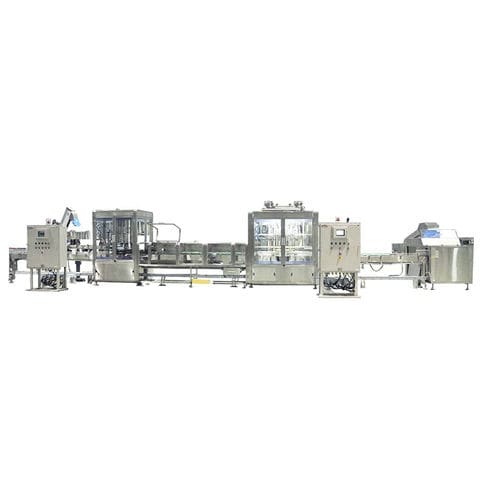

The latest PX-BFC80 packaging line is suitable for small glass bottles, plastic bottles and other packaging processes. It is mainly composed of bottle sorting + filling + capping + labeling + cartoning and other parts. The whole line is controlled by PLC, all parameter adjustments are adjusted by the touch screen, and the aviation plug is applied to the circuit connection, you do not need to supply power to each machine separately. In terms of manual protection, we use a 150mm wide protective cover, equipped with an emergency stop sensor switch, which ensures the safety of labor, and the plexiglass cover ensures the safety of product production.

The filling of fuel is very careful, explosion-proof is a must, we use explosion-proof electrical cabinets to isolate the circuit of each host to avoid external contact

Product characters :

1- High precision

2- Easy operation

3- Well-adapted

4- Human-friendly design