- Packing - Handling - Logistics

- Packing and Packaging

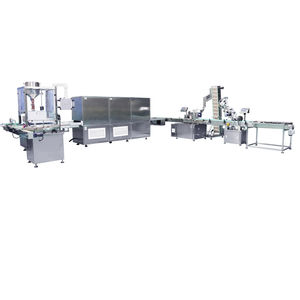

- Automatic filling machine

- Paixie Packing Machinery

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

6-head filling machine PX-BFC80automaticbottlelubricating oil

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- bottle

- Product applications

- for edible oil, lubricating oil

- Domain

- for the chemical industry

- Number of heads

- 6-head

- Other characteristics

- PLC-controlled, compact

Description

The machine adopts the principle of controlling the flow meter design, precise filling volume, is particularly suitable for filling edible oil, lubricants and other oil products, the majority of the edible oil industry and chemical industries ideal filling machinery.

The machine integrates optical, mechanical, electrical, gas in one, compact design is reasonable, simple appearance, stable performance, bottle feeding, positioning, filling, the bottles actions are done automatically. Using linear feeding bottles, pressure filling, PLC logic controller, equipped with a variety of sensors and cylinders, to achieve automatic control purposes, there are bottle filling, no bottle no filling, filling no foam, no drip, and more with the most advanced man-machine interface touch operation, easy replacement and adjustment container filling volume, no need to replace p

1.the advantage of flowmeter way: The adjustment in dosage is convenience and quick, the volume only need to be set on the touchscreen directly, considered that the vegetable oil is different in density in the different temperature, resulting in the volume setting different, we have added an automatic temperature-compensated system.

2.filling accuracy: instead of the tranditional computing type of flowmeter -- through pulse generator, now promoted by our company, adopting rotary encoder is more accurate.

3.filling speed: instead of the traditional power delivery -- pressure artesian flow, our machine adopting frequency converter to adjust the speed of filling,the efficiency highly raised. The speed can be arbitrarily adjusted on panel.

Catalogs

Other Paixie Packing Machinery products

Small bottle filling machine

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Filling system for the chemical industry

- Multi-head filler

- Side labelling machine

- Filler for the pharmaceutical industry

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Filler for the cosmetics industry

- PLC-controlled filler

- Container filler

- Piston filler

- Automatic capper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.