- Packing - Handling - Logistics

- Packing and Packaging

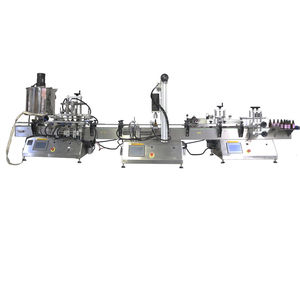

- Automatic capping machine

- Paixie Packing Machinery

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

In-line capping machine PX-CP50automaticfor bottlesfilling

Add to favorites

Compare this product

Characteristics

- Type

- in-line

- Operating mode

- automatic

- Product applications

- for bottles, filling

Description

Easy adjustments make quick change over from one cap size to the next

The whole machine supports frequency control, PLC control, and touch screen display, and is suitable for different filling lines and packaging lines.

The torquing head would stop rotating after reaching the designed torquing force to avoid damaging the cap and bottle.

Photoelectric sensor detection would stop in case of lacking bottles or bottle jamming and would resume automatic operation after recovery.

A replaceable torquing head is provided to meet the requirements for locking and pressing different bottle caps.

Parts like the electrical control are all sealed to prevent materials from affecting the service life of electrical components.

Easy to disassemble, clean, maintain and repair.

Manned supervision is not required for normal production; equipped with various automatic protection devices.

The shell of the machine is made of stainless steel 304, which conforms to the GMP requirement.

Catalogs

No catalogs are available for this product.

See all of Paixie Packing Machinery‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Filling system for the chemical industry

- Multi-head filler

- Side labelling machine

- Filler for the pharmaceutical industry

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Filler for the cosmetics industry

- PLC-controlled filler

- Container filler

- Piston filler

- Automatic capper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.