- Packing - Handling - Logistics

- Packing and Packaging

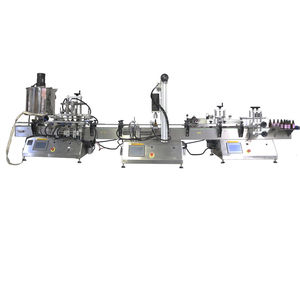

- Gripper capping machine

- Paixie Packing Machinery

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

In-line capper PX-CP50gripperrotaryscrew

Add to favorites

Compare this product

Characteristics

- Type

- rotary, pneumatic, screw, in-line, gripper, vacuum

- Operating mode

- automatic, manual

- Product applications

- for bottles, jar

- Other characteristics

- hand-held, inline

- Throughput

80 p/min

Description

inline capper including: Heavy duty stainless steel frame, C-frame design for easy addition to any conveyor, Pneumatic cap start tamp station. Individual spindle set speeds, Intelligent electronic single touch torque control, Powered height adjustment, On-the-fly speed and torque adjustment, Spring loaded spindles for reduced cap damage and disk wear, Cantering bottle grippers to accomodate odd shaped containers. Model High Capacity 12 cubic foot closure elevator / orientator hopper, variable speed, adjustable angel, 12″ wide belt. Curently set up for 78mm x 17mm lids.

Rated at up to 80 bottles per minute with 33mm spin on caps

Feeds left to right

Adjustable cap chute (normally 22mm to 53mm)

Vibratory feeder with 18″ stainless steel bowl

3 cubic foot top hopper

Two DC drive motors with variable speed controllers

No change parts required Hand knob for spindle spacing adjustment

Hand crank for height adjustment

Hand knob for gripper belt adjustment

Caster mounted for portability

One year warranty with free replacement parts (excluding cap tightening discs and belts)

Catalogs

No catalogs are available for this product.

See all of Paixie Packing Machinery‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Filling system for the chemical industry

- Multi-head filler

- Side labelling machine

- Filler for the pharmaceutical industry

- Labeling machine for the food industry

- Labeler for the cosmetics industry

- Filler for the cosmetics industry

- PLC-controlled filler

- Container filler

- Piston filler

- Automatic capper

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.