- Industrial machines and equipment

- Welding and Assembly

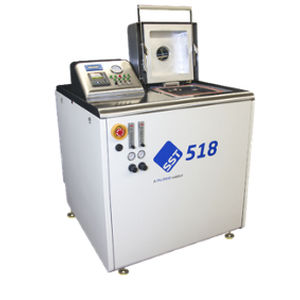

- Soldering machine

- PALOMAR TECHNOLOGIES

Soldering oven SST 5100

Add to favorites

Compare this product

Description

The SST 5100 is a vacuum and pressure furnace that provides precise automatic control of heating and cooling ramp rates. This system allows for heating up to 500°C and cooling in an inert gas environment from vacuum levels below 50 millitorr to pressures up to 40 psig. An unlimited number of process profiles can easily be created and stored in the controller. Process heating is provided over the entire work area by a close-coupled planar infrared heating element. The system is designed for high production flux-less void-free soldering.

QuikCool™ Option for SST 5100

Adding the QuikCool™ to the SST Model 5100 reduces cycle time and increases throughput of the package assembly process. QuikCool™ is a patent pending auxiliary cooling unit designed to rapidly reduce temperature in an SST 5100 Vacuum Chamber.

Processes

Void-Free Die Soldering. Void-free die and substrate solder attach is used to create a uniform thermal interface for high-reliability microelectronic devices.

Hermetic Package Sealing. Hermetic package sealing uses solder or glass to create a barrier to moisture which will damage sensitive electrical circuit components.

Selected 5100 Options

Oil-sealed or dry vacuum pump

Multiple temperature zone measurement

Moisture and oxygen analyzers

Illuminated chamber viewport

Additional process gas input

Rapid cooling system

Various heated target plate materials

Custom component fixtures

Cooling water recirculator

Castors

Light tree

Catalogs

No catalogs are available for this product.

See all of PALOMAR TECHNOLOGIES‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.