Characteristics of transparent conductive films

Transparent conductive films have the function of transmitting both electricity and visible light. ITO (Indium Tin Oxide) has been widely used as a transparent electrode for various applications, such as touch displays or solar battery cells.

ITO generally having a resistance of 10s or 100s Ω/sq., in order to meet the demand for lower resistance required in recent years ITO has to be applied thickly, however that causes problems like transmissivity loss or color change (yellowing).

To solve these problems, metal mesh has been developed as an alternative of ITO.

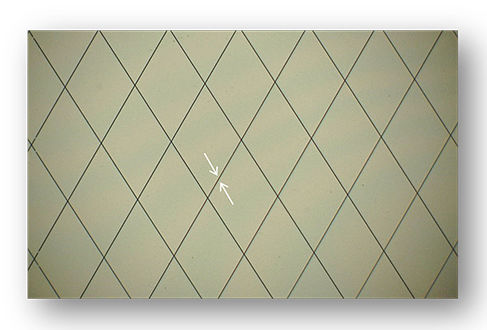

Conventional etching type metal mesh

Etching method is generally used to produce metal meshes, but there is a trade-off between lower resistance and finer wiring lines. When large size is required, transmissivity is sacrificed by the increased line width in order to lower the resistance.

In addition, metal remainder at the cross point, which tends to happen in the metal mesh produced by etching process, causes deterioration of appearance.

Wiring with High Aspect Ratio

As shown in the graphic, resistance value is inversely proportional to the cross-sectional area of the wire.

Therefore the cross-sectional area must be increased to keep the resistance value low.

Panasonic can make surface of film by flat

Panasonic’s metal mesh produced by its unique process has high aspect ratio wiring lines by gaining a cross-sectional area to depth direction while keeping the fine line width, achiving low resistance and excellent transmissivity at the same time.

Aspect ratio = Line depth (thickness) / Line width

Wire thinning and aperture ratio