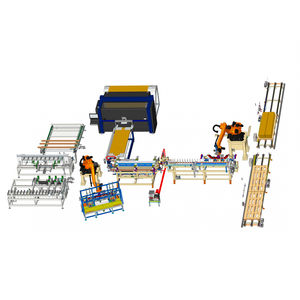

Multi-product complete packaging line Box Design 410 auto partsfor automotive applicationswindow

Add to favorites

Compare this product

Characteristics

- Product applications

- multi-product, auto parts, for automotive applications, window, for furniture, for panels, semi-automatic, door

- Other characteristics

- automatic

- Throughput

Max.: 15 p/min

Min.: 2 p/min

Description

This system was specifically designed to handle the boxes F410 or similar (e.g. 427, 411, etc.), with longitudinal as well as front and back flaps to be closed on the outside of the box.

It is ideal to pack: furniture in kits or disassembled furniture, doors, windows, shower cubicles, radiators, panels, etc. and all other items low in height but extremely flexible in length and width.

According to the boxes to be processed, the system usually features two main stations, which provide for the perfect forming and closing of the box:

1) FORMING STATION FM410

2) CLOSING STATION CM410S / VARYPACK

Due to the high level of customization of the different units that can be implemented, it is possible to reach production rates of up to 10 parcels/min.

Working Stations

1 Product Preparation Station

Area in which the loose items are prepared by an operator. In this area also transport protections may be applied if required.

2 Measuring Station

The items are measured automatically or by hand and the data is then submitted to the packaging machine to launch production of the right sized box.

3 Box Procurement

The Panotec packaging machine produces the right-sized boxes. If the production process requires large batches, the boxes can be supplied by a box manufacturer and stored on pallets/racks next to coupling station run by an operator.

4 Box Forming

Area in which the bottom of the boxes is formed automatically, mainly for box designs F410, F401 or bottom and lid designs. An operator must be assigned to form the box manually if this section is not automated.

Catalogs

No catalogs are available for this product.

See all of Panotec‘s catalogsRelated Searches

- Complete packaging line

- Case sealer

- Cardboard box/case erector

- Automatic complete packaging line

- Automatic cardboard box/case erector

- Automatic case sealer

- Adhesive tape cardboard box/case erector

- Hot-melt glue cardboard box/case erector

- Label printer-applicator

- High-speed cardboard box/case erector

- Pneumatic cardboard box/case erector

- Self-adhesive label printer-applicator

- Hot-melt glue case sealer

- Multi-product complete packaging line

- Fully-automatic complete packaging line

- High-speed complete packaging line

- Compact complete packaging line

- Case former-sealer

- Adhesive tape case former-sealer

- Packaging label printer-applicator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.