- Materials - Tools - Components

- Standard Mechanical Component

- Lipped seal

- Parker Hannifin France SAS

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Lip seal SPIelastomericfor rotating shaftsfor rotary actuators

Add to favorites

Compare this product

Characteristics

- Type

- lip

- Material

- elastomeric

- Application

- for rotating shafts, for rotary actuators, shaft, for specific applications

- Other characteristics

- labyrinth

Description

Rotary Shaft Seals

What Is the Purpose of a Seal?

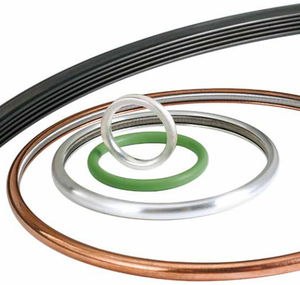

Today there is a wide selection of designs available for use in rotary applications. They range from the traditional single and double lip elastomeric configurations to PTFEbased designs. Even more complex designs incorporate multiple lips, differing materials and hybrid labyrinth designs.

The purpose of this reference guide is to assist engineers and maintenance professionals in selecting the best design for a specific application based on service life requirements and cost objectives.

One of the most common purposes of a lip seal is to protect the bearing that is used to support a shaft in a rotating application. Retaining the bearing lubricant and keeping it clean ensures maximum bearing life and increases the overall service life of the equipment. Such applications include automotive wheels, electric motors, pumps, gearboxes and large rolls used in steel and paper manufacturing.

Radial lip seals are used throughout industries in a variety of other applications under a wide range of operating conditions. These conditions can vary from high-speed shaft

rotation with light oil mist to low speed reciprocating shaft in muddy environments. Radial lip seals can be found sealing lube oil in high speed crankshaft applications for gasoline and

diesel engines that operate from the tropics to the arctic, in submarines, oil tankers, spacecraft, windmills, steel mills, paper mills, refineries, farm tractors, appliances and

automobiles. In fact, they can be found in anything that has a rotating shaft.

Catalogs

No catalogs are available for this product.

See all of Parker Hannifin France SAS‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.