- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Beverage hose

- Parker Quick Coupling Division

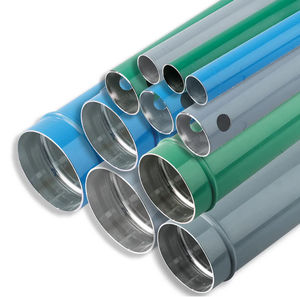

Beverage hose Transair®for compressed airNBRSBR

Add to favorites

Compare this product

Characteristics

- Use

- beverage, for compressed air

- Material

- NBR, SBR

- Applications

- for the automotive industry, for food industry applications, for aerospace applications

- Other characteristics

- flexible

- Outer diameter

Min.: 25 mm

(0.984 in)Max.: 168 mm

(6.614 in)- Pressure

15.9 bar

(230.61 psi)- Temperature

Min.: -20 °C

(-4 °F)Max.: 46.1 °C

(114.98 °F)- Delivered length

Min.: 1'00"

(0.3 m)Max.: 10'00"

(3.05 m)

Description

Transair Flexible Hoses are engineered for easy installation in tight spaces. Due to the tight bend

radius, a flexible hose can be installed in tight, close quarter areas. The use of a flexible hose

can eliminate most layout constraints and reduce the mechanical stress on a compressed air

system. These hoses are commonly used to route the compressed air line around an obstacle,

preventing pressure drop that cornes from excessive use of elbows.

Ail flexible hoses corne in fixed lengths with attached ends to eliminate the need to eut and

crimp the hose. The SBR cover is résistant to most minerai and synthetic compressor oils. Ail

hoses meet ISO 8030 for fire résistance. Transair flexible hoses are rated for use in compressed

air systems only. Parker Hannifin warrants ail Transair components to be free of defects in

material and workmanship for 10 years from the date of installation

To prevent serious bodily harm or property damage, an anti-whiplash strap (pn: 6698 99 03)

needs to be installed along with the flexible hose. Parker Transair suggests installing straps on

either side of the connection to prevent the hose from whipping in the event of a blow-off.

Markets:

• - Automotive Assembly

• - Food & Beverage

• - Packaging

• - Industrial Plants

• - Aerospace

Features/Benefits:

• - Quick connection technology

• - Modular and reusable

• - Optimum flow rate

Catalogs

General catalogue

167 Pages

Other Parker Quick Coupling Division products

Fittings and Quick Couplings

Related Searches

- PARKER fitting

- Piping

- PARKER hydraulic fitting

- Screw-in fitting

- PARKER pneumatic fitting

- PARKER metal fitting

- PARKER quick coupling

- PARKER brass fitting

- PARKER stainless steel fitting

- Flexible flexible piping

- Tapped fitting

- Tube

- Polymer fitting

- Fixed reel

- Male fitting

- PARKER female fitting

- Hose reel

- Spring rewind reel

- Poppet fitting

- Hose for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.