- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Crude oil pipe

- Parker Stratoflex

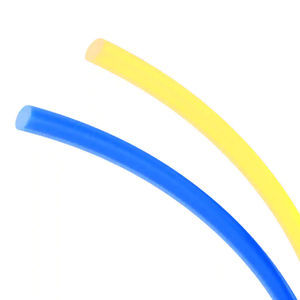

Crude oil tube 1010T10A01foodstufffor gasfor compressed air

Add to favorites

Compare this product

Characteristics

- Use

- for crude oil, foodstuff, for gas, for compressed air, for oil

- Material

- PTFE, FEP, PFA, PVDF

- Applications

- high-temperature, for medical applications, for the pharmaceutical industry, chemistry, transport, for the electronics industry, for aerospace applications, for clean rooms, for the food industry, for the food industry

- Other characteristics

- chemical-resistant, anti-static, silicone-free

- Inner diameter

Min.: 2 mm

(0.079 in)Max.: 9 mm

(0.354 in)- Outer diameter

Min.: 4 mm

(0.157 in)Max.: 12 mm

(0.472 in)- Pressure

36 bar

(522.136 psi)- Temperature

Min.: -196 °C

(-320.8 °F)Max.: 260 °C

(500 °F)- Delivered length

50 m, 100 m

(164'00" , 328'01" )

Description

Parker Legris PFA (perfluoroalkoxy) tubing offers 10 times greater durability than other fluoropolymer tubings (PTFE, FEP and PVDF) under severe chemical and mechanical conditions.

Features/Benefits:

- Great Versatility

• - Exceptional chemical inertia

• - A flexible alternative to stainless steel tubing

• - Broad range of working temperatures, from cryogenic to extreme heat

• - Non-stick properties allowing conveyance of many fluids & gases

• - Outstanding résistance to ageing

• - Fluoropolymer with the lowest permeability

• - Non-flammable

• - UV-transparent

• - Tube marking on request

• - Silicone-free

-Three Material Grades

• - Clear High Purity PFA: to cover ail applications, including those requiring maximum mechanical résistance

• - Coloured PFA: for circuit identification

• - Black Antistatic PFA: eliminates ail risk of electrostatic discharge

Applications:

• - Applications Subjected to Severe Mechanical and Chemical Conditions

• - Médical Fluids Conveying

• - Gas and Compressed Air Conveying

• - Applications Requiring Very Low and High Temperature

• - Fire Hazard Zones

• - Applications Subjected to Intensive Cleaning

• - Suitable for Fuel Cells and Clean Rooms

T

echnologies:

• - Fluoropolymer Tubing

• - PFA Tubing

• - Perfluoroalkoxy Tubing

• - Anti Static Tubing

• - Industrial Tubing

Technical Characteristics:

Materials: Perfluoroalkoxy

• - High Purity PFA

• - Translucent coloured PFA

• - Antistatic PFA

Product Types:

• Fluoropolymer (PFA) Tubing

• Fluoropolymer (PFA) Antistatic Tubing

Catalogs

No catalogs are available for this product.

See all of Parker Stratoflex‘s catalogsOther Parker Stratoflex products

Hose, Piping, Tubing and T-Slot Framing

Related Searches

- Parker Stratoflex fitting

- Parker Stratoflex piping

- Hydraulic fitting

- Screw-in fitting

- Parker Stratoflex pneumatic fitting

- Parker Stratoflex metal fitting

- Polymer hose

- Parker Stratoflex quick coupling

- Parker Stratoflex brass fitting

- Parker Stratoflex stainless steel fitting

- Parker Stratoflex elbow fitting

- Structure hose

- Flexible flexible piping

- Parker Stratoflex pipe

- Elastomer hose

- Parker Stratoflex plastic fitting

- Parker Stratoflex water hose

- T type fitting

- Compression fitting

- Parker Stratoflex male fitting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.