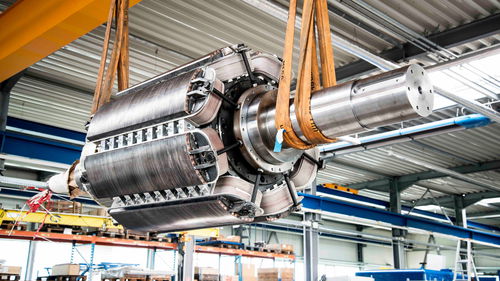

Synchronous permanent magnet motor rotor customDC1000 V

Add to favorites

Compare this product

Characteristics

- Options

- custom, DC, for synchronous permanent magnet motors

- Voltage

- 1000 V

- Power

200 kW

(271.924 hp)

Description

ROTOR WINDINGS

Whether DC or three-phase rotor windings - we take into account all special parameters when manufacturing your rotor windings.

Slipring rotor windings

We produce mush or bar windings, depending on the rated output of your machine. In addition, the mechanical machining of rotor parts, such as the manufacture of shafts, laminated cores and slipring assemblies, is also part of our product portfolio, as does the manufacture of two-pole turbine-type rotors, including balancing and skimming.

Technical specifications

• Weight: Max. 32 t

• Copper

• Insulated bars and/or enamelled wire

• For use of the VPI or Resin-Rich technology

• Minimum cross-section: 4 x 1 mm

• Cross-section 25 x 5 mm: Up to a length of max. 2 m

• Special dimensions possible by agreement

• Winding head bandage

• Up to a laminated core diameter of 1,500 mm

• Up to a shaft length of 5,000 mm

• Weight: 10 t

• Larger rotors are currently bandaged in Bitterfeld.

Three-phase squirrel-cage rotor windings

This type of windings is manufactured with copper, aluminium or special alloy bars.

Technical specifications

• Up to a weight of 32 t

• With aluminium or copper bars

• In any bar geometry

Material analyses

• Technologies used for joining:

• Welding, brazing and soft-soldering

• Open flame or induction soldering

Catalogs

No catalogs are available for this product.

See all of Partzsch‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.