- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

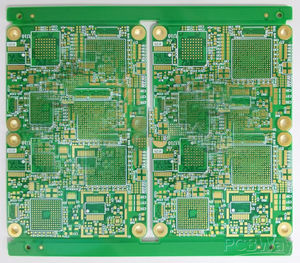

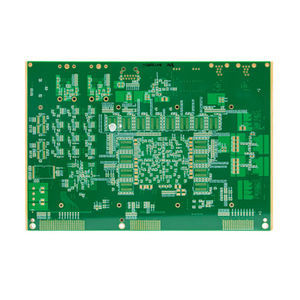

42 layers printed circuit board for industrial applications

Add to favorites

Compare this product

Characteristics

- Applications

- for industrial applications

- Number of layers

- 42 layers

Description

Type

IC test board

Material

S1000-2M

Thickness

6.9mm

Min Hole Size

0.45mm

Board thickness and via diameter ratio

15:1

Minimum spacing from hole to conductor

8mil

Surface Finish

Immersion gold(ENIG)

Application field

IC test board

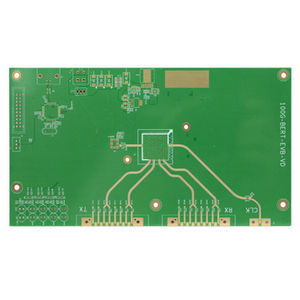

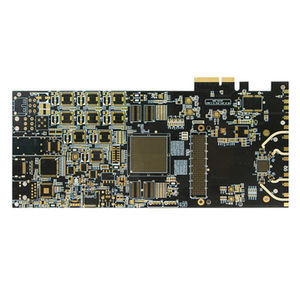

1.Up to 64 layer processing technology, the minimum trace and space is 2.5 / 2.5mil, the highest ratio of board thickness and hole diameter is 16:1.

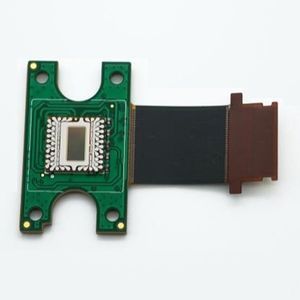

2. Long and short gold finger processing technology and high-density trace’s precision control to meet the design requirements of photoelectric communication products.

3. High-precision back-drilling technology to reduce the equivalent series inductance of vias and in case to meet the product’s integrity requirements of signal transmission;

4. Advanced metal-based and ultra-thick copper manufacturing process to meet the high heat dissipation requirements of power products.

5. High-precision mechanical and laser depth control technology to achieve multi-level step groove product’s structure and meet the different levels of assembly requirements.

6. The mature mixed pressure process realizes the mixing of FR-4 and high-frequency materials, and saves the material cost for customers under the premise of achieving the high-frequency performance of the products.

7. Advanced Anti-CAF process technology greatly improves the reliability and service life of PCB products.

8. Advanced buried capacitor and buried resistor technology greatly improve the performance of PCB products.

9. Advanced inner layer exposed technology meets the information transmission requirements of high frequency circuits.

Catalogs

No catalogs are available for this product.

See all of PCBWay‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.