- Products

- Catalogs

- News & Trends

- Exhibitions

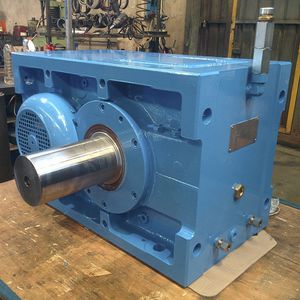

Bevel gear reducer parallel-shaftright angletransmission

Add to favorites

Compare this product

Characteristics

- Type

- bevel

- Shaft orientation

- parallel-shaft, right angle

- Applications

- transmission

Description

PCM reduction gears have been completely redesigned.

Advantages of this are the following:

A more exhaustive product range

A greater working safety and reliability due to an increased transmissible power

New optionals available for all the product range

Possibility of hunting assembly through output flanges

New types of motor connections with coupling adapter and joint, antireverse devices, locking assemblies.

Assembly positions

PCM reduction gears cases are arranged for each kind of fixing, for particular assembly positions you can contact our technical department.

Acoustic pressure level

Noise level of the new reduction gears of the “G” series has been improved thanks to:

Bevel gear pair lapping

Optimised drive ratio

Reinforced cases to restrain vibrations

Heat dissipation

Reduction gears of the “G” series have a high heat performance thanks to:

Greater exchange surface with external environment

Optimised efficiency allows reduction of heat emissions by the mechanics.

For particularly burdensome applications, auxiliary cooling systems are available.

General warning:

The following steps must be absolutely respected:

Dimensional drawings included in this catalogue are approximate, PCM reserves the right to modify dimensions without any kind of obligation.

Weight and amount of oil are approximate. Oil quantities vary based on transmission ratio and construction. Refer to the visual level indicator.

The buyer commits to protecting rotating parts against any possible contact and to respecting safety standards in each country of use.

Before starting the machine, read use and maintenance manual carefully.

Reduction gears are supplied without any lubricant.

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Gear train gearbox

- Shaft gearbox

- Transmission gearbox

- Industrial gear reducer

- Helical gear gearbox

- Low-noise gearbox

- Bevel gearbox

- Electric motor gearbox

- Machine gearbox

- Parallel-shaft gearbox

- Flange gearbox

- Modular gearbox

- Drive gearbox

- High-speed gearbox

- Machine gear reducer

- Spiral bevel gearbox

- Gearbox for marine applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.