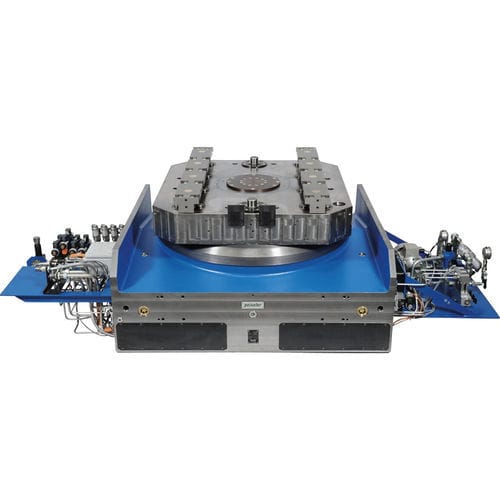

Motor-driven rotary indexing table ATD DYNverticalfor machine tools

Add to favorites

Compare this product

Characteristics

- Operation

- motor-driven

- Configuration

- vertical

- Applications

- for machine tools

- Diameter

Max.: 1,250 mm

(49 in)Min.: 125 mm

(5 in)- Weight

Max.: 18,000 kg

(39,683.21 lb)Min.: 80 kg

(176.37 lb)

Description

Our ATD dyn rotary tables with integrated direct drive enable dynamic turning of workpieces. In the technical design of the direct drives in the dividing heads, we place particular emphasis on ensuring optimum performance of our ATD rotary tables.

The ATD dyn sizes 400 to 800 can be used in S1 continuous operation. The optional cooling concepts developed by Peiseler enable a thermally stable fusion of milling and turning applications.

• Rotary tables as pallet receivers with zero-point clamping systems

• Rotary tables as pallet receivers in accordance with DIN 55201

• Attachment tables

• Built-in tables

• Slide tables

• Integrated linear x axis

Direct drives allow highly dynamic and continuous movement and with this, a constant flow of new machining concepts. Peiseler took the lead in this technology as early as 1997 with the development of the world's first subdevice with a direct drive, just as it did with the first two-axis rotary tilt table with a direct drive in 2001. Today, we are in the technologically leading position to offer you direct drives for turning operations in S1 continuous milling. Increasing machine speed while maintaining bearing rigidity at a level that is also suitable for milling enables us to combine turning and milling applications. This allows Peiseler's development engineers to use machining centres more flexibly. Direct drives use very sensitive control technology and place high demands on energy supply.

Catalogs

Main Products

68 Pages

Related Searches

- Turntable

- Electric turntable

- Horizontal turntable

- Motor-driven turntable

- Intermittent index unit

- Machine tool turntable

- Vertical turntable

- Machining head

- Electric rotary indexing table

- Compact turntable

- Machine tool rotary indexing table

- CNC rotary table

- Horizontal rotary indexing table

- Motor-driven intermittent index unit

- Direct-drive rotary table

- Machining rotary table

- Vertical rotary indexing table

- 2-axis machining head

- Tilting turntable

- Tilting rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.