- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

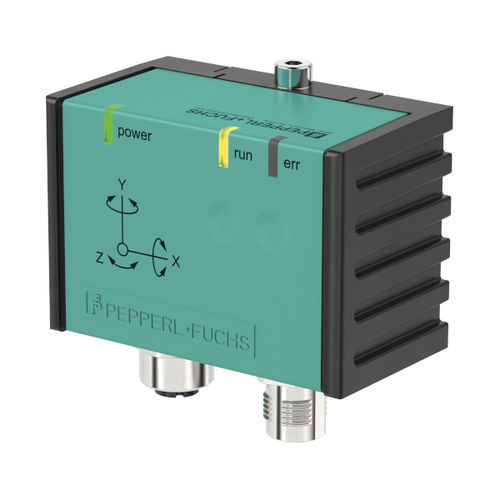

Inertial measurement unit IMU F99

Add to favorites

Compare this product

Description

Have you ever wondered how you can ensure correct measured values from your inclination sensors while your mobile machines are moving? The data of static inclination sensors is often incorrect due to external impacts, such as potholes or during acceleration. Inertial measurement units such as the IMU F99 from Pepperl+Fuchs are the ideal solution here: The IMU F99 consists of a triple-axis MEMS accelerometer and a triple-axis MEMS gyroscope. An intelligent Sensor Fusion Algorithm combines the data from the accelerometer and gyroscope to compensate for the effects of external acceleration and the actual value is displayed.

Whether for steering angle limitation on wheel loaders or the control of AGVs—the inertial measurement unit IMU F99 is the ideal solution for monitoring inclination and acceleration in dynamic applications. We have compiled six application examples of the inertial measurement unit in our blog article. Which application is yours?

Benefitsprecision

Precise Measurement

Inertial measurement units combine an acceleration sensor with a gyroscope and an intelligent Sensor Fusion Algorithm in a single device. This combination allows compensation of even dynamic movements and still ensures precise measurement.

efficiency

Increased Efficiency

The Sensor Fusion Algorithm intelligently links the various data provided by the gyroscope and the acceleration sensor. External accelerations are compensated and the user receives precise inclination data—even when the system moves, accelerates, or brakes.

Catalogs

No catalogs are available for this product.

See all of Pepperl+Fuchs SE‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Pepperl+Fuchs SE products

Inclination and Acceleration Sensors

Related Searches

- Angular encoder

- Incremental encoder

- PEPPERL & FUCHS proximity sensor

- Incremental rotary encoder

- Acceleration sensor

- PEPPERL & FUCHS cylindrical proximity sensor

- Absolute rotary encoder

- PEPPERL & FUCHS inductive proximity sensor

- Solid-shaft rotary encoder

- PEPPERL & FUCHS photoelectric sensor

- Tilt sensor

- Hollow-shaft rotary encoder

- IP67 proximity switch

- Optical rotary encoder

- Industrial rotary encoder

- Magnetic rotary encoder

- DC rotary encoder

- Distance sensor

- PEPPERL & FUCHS rectangular photoelectric sensor

- Digital tilt sensor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.