- Production Machines

- Forming Machine

- Perfect Laser Co., Ltd. (China)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

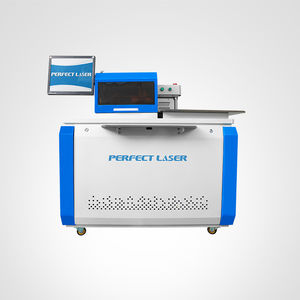

Stainless steel channel letter bending machine PEL-400aluminum

Add to favorites

Compare this product

Characteristics

- Bending material

- aluminum, stainless steel

- Processed thickness

Max.: 1.5 mm

(0.1 in)Min.: 0.5 mm

(0 in)- Processed width

150 mm

(6 in)- Feed speed

Max.: 20 m/min

Min.: 5 m/min

Description

1) Applicable Materials: Aluminum strip bending, stainless steel strip bending, iron bending, galvanized steel bending ect.

2)Applicable Industries: advertising industry, such as logos, signs, neon signs, billboards, light boxes production, outdoor advertising and other advertising production.

Automatic CNC bending machine, (also called CNC letter bending machine or character bending machine) is a new advertising production equipment, which can be used for logos, signs, neon signs, billboards, light boxes production, outdoor advertising and other advertising production.

1) Friendly man-machine interface, simple configuration, touch-screen operation. Simply enter the processing of text, graphic design files, and then the machine can process them on materials automatically.

2) A unique three-dimensional process simulation technology, two-dimensional design file to be able to display three-dimensional effects, supplemented by translation, rotation, zoom and other functions, enables full observation and monitoring of whole working process.

3) The original double-bent knife parallel bending technology to save time and greatly improve the processing efficiency, the maximum bending angle reached 130 °.

4) High precision machining, feeding precision can reach 0.01mm, bending accuracy up to 0.4 °.

5) With precision automatic calibration function, based on the way of the processing material, self-adjusting process parameters, so that it can match with a variety of engraving machines and cutting machine, meet a variety of complex embedded process accuracy as much as possible.

VIDEO

Other Perfect Laser Co., Ltd. (China) products

Channel Letter Bending Machine

Related Searches

- Bender

- Electric bender

- CNC bender

- Automatic bender

- Section bending machine

- Forming machine

- Precision bender

- Automatic forming machine

- Cutting bender

- Mechanical bending machine

- Pipe forming machine

- High-efficiency bending machine

- Multi-function bending machine

- Multipurpose bending machine

- Edging bending machine

- Box forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.