- Production Machines

- Forming Machine

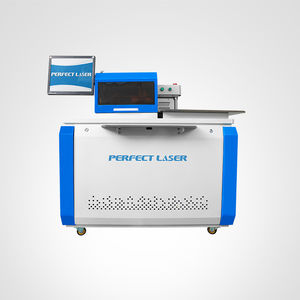

- Perfect Laser Co., Ltd. (China)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Plate channel letter bending machine PEM-1400

Add to favorites

Compare this product

Characteristics

- Bending method

- plate

- Overall length

1,500 mm

(59 in)- Overall width

1,500 mm

(59 in)- Overall height

1,250 mm

(49 in)- Weight

350 kg

(772 lb)

Description

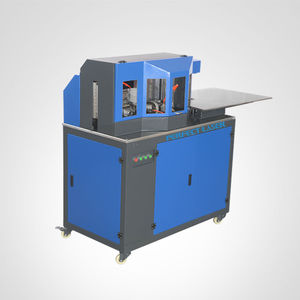

Acrylic Blister Machine, also known as plastic vacuum forming machine, is making the plasticizations of PVC, PE, PP, PET, HIPS and other thermoplastic plastic material into various shapes of advanced packaging boxes.Its compression parts are made of large steel so that it has high strength, good rigidity as well as smooth work surface. The lifting and moving platform adopts high precision four axis guidance, therefore the lifting and moving platform is stable when lifting up and down. Compared with the traditional acrylic forming machine, the water balance system is added on the basis of the original balance rack system so that the balance problem of the lifting formwork is solved thoroughly.

1.The equipment of the acrylic vacuum forming machine adopts the hydraulic lifting system, which makes the floating plate safe and smooth and the working pressure more strong,so that it ensures the molding more convenient and quick.

2.The acrylic vacuum forming machine system is powerful and can always be in the ideal negative pressure state so that it is more convenient to use.

3.The softening box is equipped with automatic constant temperature control system and unique zoning heating function, therefore, so that the acrylic vacuum forming machine can be set freely according to different heating requirements

4.With advanced technology, the material can be pressed and cooled in one time. The model can also be individually sucked or pressed separately according to the different effects of the lamp box and the words.

5.The acrylic forming machine's work force is up to 12 tons; the power is 380V and 220V (customerised), which can be easy in the factory or shop operation.

Catalogs

No catalogs are available for this product.

See all of Perfect Laser Co., Ltd. (China)‘s catalogsOther Perfect Laser Co., Ltd. (China) products

Channel Letter Bending Machine

Related Searches

- Bender

- Electric bender

- CNC bender

- Automatic bender

- Section bending machine

- Forming machine

- Precision bender

- Automatic forming machine

- Cutting bender

- Mechanical bending machine

- Pipe forming machine

- High-efficiency bending machine

- Multi-function bending machine

- Multipurpose bending machine

- Edging bending machine

- Box forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.