- Industrial machines and equipment

- Printing, Marking and Engraving

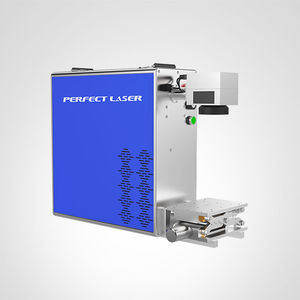

- Fiber laser marking machine

- Perfect Laser Co., Ltd. (China)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Fiber laser marking machine PEDB-480metalplasticaluminum

Add to favorites

Compare this product

Characteristics

- Technique

- fiber laser

- Material

- metal, plastic, aluminum

- Applications

- for electronic components

- Other characteristics

- compact, automatic, air-cooled, continuous

- Power

500 W

(0.68 hp)- X travel

110 mm

(4.33 in)- Y travel

110 mm

(4.33 in)- Speed

7,000 mm/s

Description

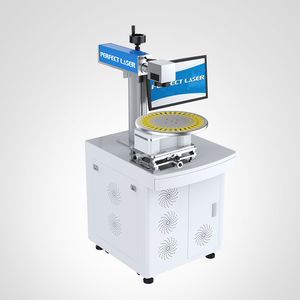

Compared with other laser marking machine, PEDB-480 laser engraving metal machine adopts a 5 megapixel coaxial CCD camera. The camera first develops the template of the product, determines the shape of the product, saves it as a standard template, and takes photos of the products to be processed during normal processing. Through computer’s quick template comparison and position positioning, the product can be precisely processed after adjustment. The laser engraving metal machine can realize automatic positioning, and the positioning accuracy can be as high as 0.02 mm.

1.The shape of the processed product can be recognized by round, square and irregular shapes. This process is especially suitable for small products, which can eliminate the processing of positioning trays and fixed fixtures, which greatly saves the laser marking processing cycle.

2.The laser engraving metal machine improves the marking quality and the pass rate which save times, effort and cost of the users.

3.The visual positioning marking can save labor and improve production efficiency. Thus, the laser engraving metal machine is suitable for laser marking processing in the assembly line and save lots of the investing cost.

4.The laser engraving metal machine adopts advanced technology with better optical mode and lower power consumption, which supports longer time of stable operation.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Perfect Laser Co., Ltd. (China)‘s catalogsOther Perfect Laser Co., Ltd. (China) products

Laser Marking Machine

Related Searches

- Perfect Laser Co. Ltd. marking machine

- Perfect Laser Co. Ltd. laser marking machine

- Perfect Laser Co. Ltd. metal marking machine

- Perfect Laser Co. Ltd. benchtop marking machine

- Perfect Laser Co. Ltd. printing machine

- Perfect Laser Co. Ltd. industrial printer

- Perfect Laser Co. Ltd. plastic marking machine

- Perfect Laser Co. Ltd. high-speed marking machine

- Perfect Laser Co. Ltd. industrial marking machine

- Perfect Laser Co. Ltd. automatic marking machine

- Perfect Laser Co. Ltd. compact marking machine

- Perfect Laser Co. Ltd. fiber laser marking machine

- Perfect Laser Co. Ltd. color printing machine

- Perfect Laser Co. Ltd. laser engraving machine

- Perfect Laser Co. Ltd. aluminum marking machine

- Perfect Laser Co. Ltd. dot peen marking machine

- Perfect Laser Co. Ltd. color printer

- Perfect Laser Co. Ltd. integration marking machine

- Desktop printer

- Perfect Laser Co. Ltd. hand-held marking machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.