- Production Machines

- Forming Machine

- Pipe forming machine

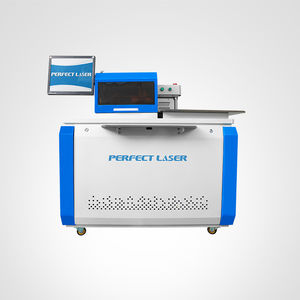

- Perfect Laser Co., Ltd. (China)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Pipe forming machine PE-1224Mboxacrylicautomatic

Add to favorites

Compare this product

Characteristics

- Product handled

- for pipes, box

- Treated material

- acrylic

- Operating mode

- automatic, vacuum, continuous

Description

The automatic vacuum forming machine is used to make 2-3mm acrylic into flat, curved, and spherical characters, fonts, and light boxes. The large vacuum forming machine consists of a starting balance device, a vacuum pump, 8 air cylinders, and 12 heating tubes.

The automatic vacuum forming machine supports three processing modes: single suction, single pressure and simultaneous suction pressure.

Different modes can bring different forming effects.

1.Intelligent temperature control, heating box use the shaped reflector and thickened insulation layer, heating fast and with good

insulation and safety performance.

2.Customized heaters from factory which can run 24hours continuously, service life up to 8000-10000 hours, the working temperature difference is±5 degrees, which can ensure even softening temperature of plate.

3.Working platform is made of steel which is high temperature resistant and long life service.Adopt single mould forming, easy operation, lower raw material and labor cost.

4. The aluminum alloy press frame controlled by two cylinders is more convenient to use and improves the sealing and forming

effect.

5.Add movable platform controlled by two cylinder to ensure smooth lifting & increase the molding height.

6.More powerful vacuum pump , finish vacuum forming sample more beautiful

7.Air storage tank is installed to extend the service life of vacuum pump, at the moment of moulding, the suction force is stronger and the forming effect is better.

8.Add blowing function, not only easy to demoulding, and can complete the ball blow molding.

Catalogs

No catalogs are available for this product.

See all of Perfect Laser Co., Ltd. (China)‘s catalogsOther Perfect Laser Co., Ltd. (China) products

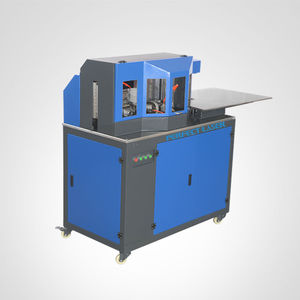

Channel Letter Bending Machine

Related Searches

- Bender

- Electric bender

- CNC bender

- Automatic bender

- Section bending machine

- Forming machine

- Precision bender

- Automatic forming machine

- Cutting bender

- Mechanical bending machine

- Pipe forming machine

- High-efficiency bending machine

- Multi-function bending machine

- Multipurpose bending machine

- Edging bending machine

- Box forming machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.