- Production Machines

- Cutting Machine

- CO2 laser cutting machine

- Perfect Laser Co., Ltd. (China)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

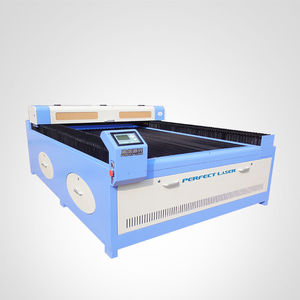

CO2 laser cutting machine PEDK-160130for fabricsfor paperwith control software

Add to favorites

Compare this product

Characteristics

- Technology

- CO2 laser

- Material

- for fabrics, for paper

- Control type

- with control software

- Associated function

- marking

- Applications

- for industrial applications

- Workpiece loading

- automated loading/unloading

- Phase

- single-phase

- Configuration

- large-format

- Other characteristics

- automatic, precision

- X travel

1,600 mm

(62.99 in)- Y travel

1,300 mm

(51.18 in)- Laser power

70 W, 100 W, 150 W

Description

Visual laser cutting machine combines laser cutting with visual recognition system.

Visual laser cutting machine has two scanning modes of scanning flight scanning and mark spot scanning, which is very suitable for cutting digital printing fabrics of various shapes and sizes.

The camera scans the fabric, detects and recognizes the printed contours and transmits them to the computer and cuts the selected design with speed and accuracy.

Conveyor belts and automatic feeders guarantee continuous cutting, saving time and increasing production speed.

1. Faric laser cutting machine realizes seamless and highly automated digital printing process, simplifies the process and saves 60% labor, improves the work efficiency.

2. Achieving precise cutting through highly efficient automated visual scanning system, reducing 35% loss on transfer paper/printing time/fabric. Scrap rate is drastically reduced to ensure product quality.

3. Faric laser cutting machine can save 10% of ink in consumable materials.

4. The co2 laser cutting machine saves space and reduces zero stock loss.

★ Application

1. Application Area

CAD vision laser marking machine can be applied to jerseys, cycling wear, fitness wear, striped and checkered garments, printed sportswear, sweatshirts,etc.

2. Application industry

Typical application:sportswear,banners,adhesive labels,home textile.

Catalogs

No catalogs are available for this product.

See all of Perfect Laser Co., Ltd. (China)‘s catalogsOther Perfect Laser Co., Ltd. (China) products

Co2 Laser Engraving and Cutting Machine

Related Searches

- Perfect Laser Co. Ltd. cutting machine

- Perfect Laser Co. Ltd. metal cutting machine

- Perfect Laser Co. Ltd. CNC cutting machine

- Perfect Laser Co. Ltd. laser cutting machine

- Perfect Laser Co. Ltd. cutting machine for industrial applications

- Perfect Laser Co. Ltd. automatic cutting machine

- Knife cutting system

- Perfect Laser Co. Ltd. high-precision cutting machine

- Perfect Laser Co. Ltd. sheet metal cutting machine

- Perfect Laser Co. Ltd. high-speed cutting machine

- Perfect Laser Co. Ltd. fiber laser cutting machine

- Perfect Laser Co. Ltd. tube cutting machine

- Perfect Laser Co. Ltd. plastic cutting machine

- Perfect Laser Co. Ltd. precision cutting machine

- Perfect Laser Co. Ltd. fabric cutting machine

- Perfect Laser Co. Ltd. aluminum cutting machine

- Perfect Laser Co. Ltd. stainless steel cutting machine

- Perfect Laser Co. Ltd. sheet cutting machine

- Perfect Laser Co. Ltd. metal fabrication cutting machine

- Perfect Laser Co. Ltd. cutting machine for the automotive industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.